Vacuum Excavation Techniques: Ensure Safe & Efficient Subsurface Work

Elevating Safety and Accuracy in Subsurface Excavation Through Hydrovac Innovations

In the realm of underground utility installation and hazard mitigation, vacuum excavation—particularly hydrovac technology—has transformed traditional trenching and borehole procedures. This sophisticated approach enables excavation with minimal surface disruption, reducing risks associated with utility strikes and environmental impact. As infrastructure projects demand higher precision and safety standards, understanding the latest advancements in hydrovac excavation techniques becomes essential for practitioners committed to excellence.

Why Fine-Tuned Control and Real-Time Monitoring Are Critical in Modern Excavation

Contemporary hydrovac systems integrate advanced sensors and real-time monitoring mechanisms, allowing operators to exercise unprecedented control during excavation. This digital augmentation not only enhances safety by preventing accidental damages but also ensures compliance with strict regulatory standards. The deployment of such systems demands a profound comprehension of soil behavior, fluid dynamics, and contextual site conditions, underpinning the importance of expert knowledge in choosing the appropriate hydrovac strategy.

Leveraging LSI Keywords to Achieve Semantic Depth in Trenching and Borehole Operations

In-depth familiarity with related terms such as hydrovac trenching strategies and precision-focused vacuum excavation methods enhances content relevance and authority. Applying semantic SEO principles ensures technical content resonates with both search engines and industry experts, fostering trust and facilitating knowledge sharing across professional networks.

What are the optimal methodologies to mitigate soil heterogeneity effects during hydrovac operations?

soil variability significantly influences pressure control and excavation efficiency. Employing geotechnical assessments and adaptive techniques such as streamlined vacuum trenching methods ensures stability and minimizes risk of trench collapse or utility damage. Combining expert soil analysis with cutting-edge equipment calibration forms the backbone of successful, safe subterranean work.

For field practitioners aiming to refine their expertise, exploring comprehensive resources like top techniques in hydrovac excavation can provide valuable insights. Engaging with specialized professional communities also opens avenues for sharing best practices and emerging innovations.

To stay at the forefront of underground infrastructure safety and efficiency, continual learning and adaptation of the latest vacuum excavation strategies are imperative. Take the opportunity to contribute your field insights or explore related expert content for a deeper understanding of this evolving discipline.

Adapting to Subsurface Complexity with Layered Excavation Strategies

Modern underground work increasingly encounters complex soil compositions, from unstable clays to rocky formations, necessitating adaptable and proactive excavation methodologies. Incorporating layered excavation plans allows operators to modify techniques dynamically, minimizing risks and optimizing results. For instance, integrating advanced borehole hydrovac techniques enables precise drilling in heterogeneous conditions, reducing utility strikes and environmental impact. This approach demands comprehensive geotechnical data analysis combined with real-time monitoring to adjust parameters effectively.

Can Smart Technologies Transform the Face of Hydrovac Site Management?

Emerging smart technologies, such as AI-powered sensors and machine learning algorithms, are poised to revolutionize site management in subterranean excavation. These innovations facilitate proactive decision-making, predictive maintenance, and enhanced safety protocols by analyzing vast datasets collected during operations. For example, AI can detect abnormal soil behavior or equipment anomalies, prompting immediate adjustments or halting work to prevent hazards. Such technological integrations ensure that practices stay compliant with evolving safety standards while boosting efficiency. To explore how these systems are already influencing industry standards, consult trusted resources like stratified vacuum excavation strategies for 2025.

What tools and frameworks can experts employ to assess and improve excavation safety proactively?

Adopting comprehensive risk assessment frameworks rooted in Safety Management Systems (SMS) and incorporating leading-edge analytics tools provides a structured pathway to mitigate underground excavation hazards. These systems facilitate ongoing hazard identification, staff training, and process optimization, aligning with authoritative safety standards outlined by industry leaders. Integrated with streamlined vacuum excavation safety protocols, such tools empower teams to preemptively address issues, ensuring higher safety and operational reliability. Flexibility and continuous improvement are key; thereby, practitioners should regularly review safety data and incorporate innovations from sources like top techniques for safe underground work.

If you’re aiming to elevate your excavation safety standards or want access to cutting-edge tools, engaging with professional safety communities or subscribing to industry updates can provide ongoing value and insights into emerging best practices.

,

Innovative Automation Solutions Transforming Subsurface Digging Challenges

Automation integration within hydrovac systems marks a paradigm shift, enabling operators to achieve unprecedented levels of precision and safety. Advanced robotic arms and autonomous monitoring platforms can now analyze soil conditions, adjust pressures, and navigate complex underground environments with minimal human intervention. This synergy not only accelerates project timelines but also significantly reduces human error, which has historically been a critical factor in utility strikes and accidental damages.

Bridging Data Analytics and Soil Science for Smarter Operations

The convergence of big data analytics with geotechnical insights empowers underground excavation teams to predict soil behavior accurately. By analyzing historical excavation data, soil classification models, and environmental factors, operators can preemptively tailor their approach to diverse soil types, leading to optimized energy consumption and reduced risk of collapse or utility damage. For instance, machine learning algorithms trained on vast datasets can flag potential problem zones before excavation begins, facilitating proactive planning.

Are AI and Sensor Fusion the Future of Real-Time Decision Making in Hydrovac Work?

By merging sensor data — such as acoustic emissions, soil moisture levels, and stress indicators — with AI-driven decision frameworks, excavators gain a dynamic, real-time understanding of subterranean conditions. This holistic sensor fusion enables instant adjustments to operational parameters, ensuring equilibrium between efficiency and safety. Cutting-edge systems incorporate predictive analytics to forecast soil instability, guiding operators in real-time to shift techniques or pause work as necessary. To dive deeper into the latest sensor fusion technologies reshaping underground work, consider consulting specialized publications like the integration of advanced sensors in excavation technology.

How can integrating augmented reality (AR) enhance underground utility detection and avoid costly mistakes?

Augmented reality overlays, powered by real-time data, allow field crews to visualize underground infrastructures directly on-site, aligning virtual models with physical environments. This technology enables precise positioning of boreholes, trenches, and utility lines, offering an immersive perspective that mitigates the risk of misjudgment. Moreover, AR can guide less experienced operators through complex procedures, reducing dependency on expensive trial-and-error methods. For a comprehensive understanding of AR’s role in modern excavation safety protocols, industry case studies and pilot programs provide valuable insights.

To unlock higher levels of excavation precision and safety, professionals should actively explore integrations of automation, data analytics, and visualization tools. Continuous education through specialized training modules and industry workshops will prepare teams to leverage these innovations fully, elevating operational standards across diverse project scopes.

Harnessing the Power of Advanced Soil Characterization Techniques in Hydrovac Operations

Accurate soil profiling is the cornerstone of efficient and safe hydrovac excavation. Techniques such as cone penetration testing (CPT) and high-resolution geophysical surveys provide critical insights into subsurface variability, enabling operators to adapt their approach preemptively. Integrating these methods with real-time monitoring systems facilitates dynamic decision-making, sharply reducing the risk of utility strikes and trench collapses. As soil heterogeneity remains a persistent challenge, embracing these sophisticated characterization tools empowers engineers to tailor excavation parameters precisely, ensuring optimal safety margins.

What Role Do Interactive Geospatial Mapping Tools Play in Managing Subsurface Risks?

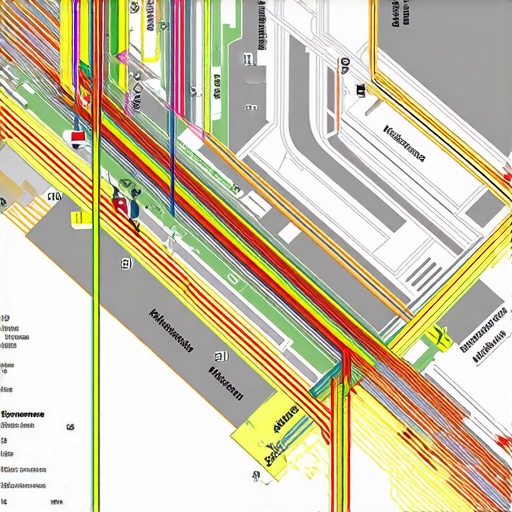

Advanced geospatial technologies—most notably 3D underground utility mapping and augmented reality overlays—bring a significant leap in subsurface risk mitigation. These tools synthesize data from multiple sources, providing detailed visualizations that guide excavation in real-time. When integrated into hydrovac workflows, such mapping systems reduce guesswork, expedite planning, and enhance team coordination. Industry leaders highlight their influence on project efficiency and safety, citing case studies where geospatial precision significantly curtailed costly errors.

Visualize an interactive geospatial map overlaying underground utility lines with hydrovac visualization tools, illustrating the integration of 3D mapping in underground excavation projects.

Why Embracing Machine Learning Transforms Subsurface Strategy Optimization

Machine learning algorithms are increasingly pivotal in predicting soil behavior and optimizing excavation parameters. By analyzing large datasets encompassing soil types, historical excavation outcomes, and environmental conditions, these systems generate predictive models that inform decision-making. This proactive approach not only streamlines operations but also enhances safety, as potential hazards are identified before ground-breaking begins. High-stakes projects involving complex subsurface conditions serve as testaments to the transformative impact of data-driven strategies, bolstering confidence in hydrovac applications amidst challenging terrains.

Can Autonomous Hydrovac Units Redefine Construction Safety and Precision?

Autonomous hydrovac technology, equipped with sensor suites and adaptive control algorithms, promises a new era of underground excavation. Freed from manual operation, these units can conduct meticulous work in hazardous or hard-to-reach environments, minimizing human exposure to risks. Precise positioning, obstacle detection, and soil assessment are executed seamlessly, translating into enhanced safety and productivity. Industry pioneers are investing heavily in these innovations, aiming to set new standards in underground utility installation and hazard mitigation. The advent of such systems necessitates a reevaluation of safety protocols and training programs within the industry.

How can industry professionals leverage emerging cybersecurity frameworks to protect operational data during advanced hydrovac deployments?

As hydrovac systems become increasingly interconnected through IoT and cloud-based platforms, safeguarding sensitive operational data becomes imperative. Implementing robust cybersecurity frameworks, including encryption, multi-factor authentication, and intrusion detection systems, ensures the integrity of critical information. Regular security audits and staff training further bolster defenses against cyber threats, which could compromise safety or lead to project delays. Experts recommend collaborating with cybersecurity specialists to develop tailored protocols aligning with industry standards such as NIST or ISO 27001, thus maintaining both technological innovation and data security compliance.

Expert Strategies That Redefine the Hydrovac Landscape

Harness the latest in geotechnical assessments to anticipate soil heterogeneity and adapt your approach proactively. Deploy layered excavation plans that dynamically respond to subsurface complexity, minimizing utility strikes and environmental impact. Leverage integrated data analytics to forecast soil behavior, leading to smarter, safer operations. Invest in AI-powered sensors and autonomous systems to elevate precision, reduce human error, and accelerate project timelines. Cultivate cross-disciplinary expertise, blending soil science, robotics, and cybersecurity to stay ahead in underground innovation.

Key Resources to Deepen Your Mastery

- Effective Hydrovac Trenching Strategies – A comprehensive guide offering practical techniques for reliable site preparation.

- Vacuum Excavation Techniques for Precise Infrastructure – Explore advanced methods tailored for complex underground conditions.

- Geotechnical Assessment Tools for Safe Excavation – Dive into innovative assessment technologies that inform safer excavation strategies.

- AI Integration in Hydrovac Operations – Understand how artificial intelligence is transforming site safety and efficiency.

- Cybersecurity Measures in Autonomous Excavation Systems – Learn best practices to protect sensitive operational data amidst increasing digitalization.

The Broader Perspective for Industry Leaders

Innovative excavation techniques, empowered by data science and automation, are revolutionizing subsurface work. Embracing these advancements not only enhances safety but also boosts operational reliability. As the field evolves, the fusion of soil science, AI, and cybersecurity becomes paramount. Industry professionals who proactively integrate these cutting-edge strategies position themselves at the forefront of a safer, more efficient underground infrastructure landscape. Engage with expert communities, contribute your insights, and stay abreast of emerging technologies to shape the future of hydrovac operations.