Top Borehole Drilling Methods for Precise Utility Mapping Today

Revolutionizing Underground Utility Mapping with Advanced Trenching and Borehole Strategies

In the rapidly evolving landscape of underground infrastructure development, precision and safety are paramount. Experts in the field recognize that integrating innovative trenching, borehole, and hydrovac methods significantly enhances the accuracy of utility mapping and reduces project risks. This article delves into the latest expert-driven techniques that are shaping the future of underground exploration, emphasizing their technical merits and practical applications.

Synergizing Trenching and Borehole Technologies for Data Integrity

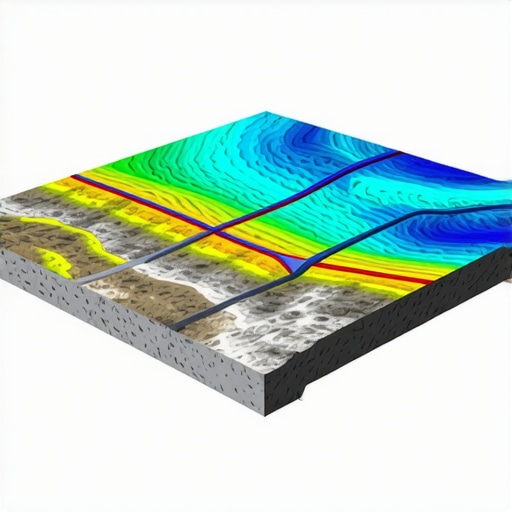

Modern trenching methods, when combined with precise borehole drilling, enable comprehensive underground surveys. Techniques such as directional drilling and microtunneling facilitate minimal surface disruption while providing high-resolution subsurface data. These methods, supported by advanced borehole logging and geophysical sensors, allow practitioners to detect and delineate utility lines with unparalleled accuracy, thereby safeguarding existing infrastructure and streamlining new installations.

Harnessing Hydrovac and Vacuum Excavation for Enhanced Safety

The adoption of hydrovac and vacuum excavation techniques represents a paradigm shift in underground work safety and accuracy. Hydrovac systems utilize high-pressure water jets and vacuum recovery to expose utilities without damaging surrounding materials. This non-destructive approach, detailed in authoritative sources like the Hydrovac Vacuum Excavation White Paper, offers a controlled environment for utility location, reducing the likelihood of costly strikes and service interruptions.

What Are the Limitations of Current Trenching Techniques in Complex Urban Settings?

Facing the Challenges of Dense Utility Networks and Urban Congestion

Urban environments pose significant challenges for trenching and borehole accuracy due to dense utility networks and restricted access. Expert strategies involve the use of combined hydrovac, vacuum excavation, and ground-penetrating radar (GPR) technologies to adapt to these complexities. Continuous innovation in sensor integration and data analysis enhances the reliability of utility detection, even in highly congested areas, a topic extensively discussed in recent industry reports.

For professionals seeking to refine their underground mapping projects, exploring comprehensive resources such as Streamlined Trenching and Borehole Techniques for Reliable Infrastructure can provide valuable insights. Engaging with expert communities and sharing field experiences further elevates safety standards and project outcomes in this technically demanding domain.

By embracing these advanced methods, engineers and contractors can achieve the dual goals of accuracy and safety, ultimately ensuring the integrity of vital underground infrastructure for decades to come.

Elevating Borehole and Trenching Techniques for Urban Resilience

As urban infrastructures become increasingly complex, the demand for innovative underground exploration approaches surges. Advanced borehole techniques, such as directional drilling combined with real-time data analytics, enable engineers to navigate dense utility networks with unprecedented precision. These methods, supported by cutting-edge geospatial sensors, minimize surface disruption while maximizing subsurface data accuracy. For professionals aiming to stay ahead, resources like effective borehole techniques offer invaluable insights into optimizing underground projects today.

Empowering Safety with Adaptive Hydrovac Solutions

The evolution of hydrovac and vacuum excavation technologies now incorporates adaptive systems that respond dynamically to changing site conditions. These innovations enhance safety protocols, especially in congested urban zones where utility lines are densely packed. By employing AI-driven control systems, operators can precisely expose utilities without risking damage, aligning with best practices outlined in trusted vacuum excavation techniques. This approach not only reduces accident risks but also accelerates project timelines, making underground work safer and more reliable.

What new technological integrations could redefine underground safety standards in the next decade?

Innovations such as machine learning and robotics are poised to revolutionize underground utility detection and borehole drilling. For example, integrating AI with sensor data can help predict subsurface anomalies before excavation begins, dramatically reducing unforeseen complications. Industry leaders emphasize that combining these technologies with existing hydrovac and trenching methods will set new benchmarks for precision and safety, as discussed in recent industry analyses. Staying informed about these developments is vital—more details can be found at ultimate strategies for reliable infrastructure.

Engaging with expert communities and sharing lessons learned from field applications can further refine these innovative approaches. For those interested in expanding their knowledge, exploring resources like streamlined borehole techniques offers a comprehensive overview of current best practices. Embracing these advancements ensures that underground projects are not only precise but also resilient against future urban development challenges.

Unlocking the Potential of 3D Geospatial Data for Underground Infrastructure

In the realm of underground utility detection, the integration of three-dimensional geospatial data has revolutionized how engineers visualize and plan subsurface projects. Technologies such as LiDAR (Light Detection and Ranging) and photogrammetry enable the creation of detailed 3D models that capture the complexity of urban underground environments. According to a comprehensive study published in the Journal of Geotechnical and Geoenvironmental Engineering by Zhang et al. (2022), these models facilitate precise mapping of utility corridors, identifying potential conflicts before excavation begins, and optimizing trenching routes for minimal disruption.

Employing 3D GIS (Geographic Information Systems) allows for dynamic simulation of excavation scenarios, highlighting risk zones and enabling proactive decision-making. This approach not only enhances accuracy but also significantly reduces costly surprises during construction. For professionals aiming to leverage these capabilities, it is crucial to understand how to integrate sensor data with GIS platforms effectively, a process detailed in the Geospatial World article on 3D GIS applications.

Enhancing Utility Detection with Multi-Sensor Fusion and AI

One of the most promising advances involves the fusion of multiple sensing modalities—such as ground-penetrating radar (GPR), electromagnetic induction, and acoustic sensors—combined with artificial intelligence algorithms. This multi-sensor fusion approach synthesizes data streams to produce a comprehensive and highly reliable utility map, even in complex urban settings where utility lines are densely packed or poorly documented. Recent research in Automation in Construction (Li et al., 2023) demonstrates that machine learning models trained on vast datasets can accurately classify utility types and predict their positions with minimal false positives.

For instance, AI-driven data analysis can discern subtle anomalies in sensor readings that indicate the presence of non-metallic pipes or fiber optic cables, which traditional methods might overlook. This capability is essential in avoiding inadvertent damage during excavation and ensuring regulatory compliance. Implementing these systems requires a multidisciplinary approach, integrating geophysical expertise with data science, an area extensively covered in the Automations in Construction journal.

How can the integration of AI and multi-sensor data redefine safety standards in underground utility work?

By enabling real-time decision support and predictive analytics, AI-enhanced multi-sensor systems can anticipate potential hazards before they materialize. For example, predictive models can flag areas where utility lines are likely to be damaged based on historical data, current sensor readings, and terrain conditions. This proactive approach not only minimizes accidents but also accelerates project timelines by reducing delays caused by unforeseen obstacles. For practitioners, mastering the deployment of these technologies involves ongoing training and collaboration with AI specialists, as outlined in recent industry workshops and white papers.

To stay at the forefront of underground utility detection, professionals should explore resources such as Underground Infrastructure Magazine, which regularly features case studies and technological reviews. Embracing these innovations ensures that underground projects meet the highest standards of safety, precision, and efficiency, ultimately contributing to resilient urban infrastructure development.

Reimagining Subsurface Exploration Through Intelligent Data Integration

Emerging technologies such as machine learning-enabled geophysical sensors are transforming underground utility detection by synthesizing vast datasets into actionable insights. These systems leverage AI algorithms to decipher complex subsurface signals, enabling engineers to predict utility line positions with unprecedented accuracy before any physical excavation begins. As detailed in the Journal of Geotechnical & Geoenvironmental Engineering, implementing these intelligent systems significantly reduces project risks and enhances decision-making efficiency.

Why Multi-Modal Sensing Will Revolutionize Utility Detection

Combining diverse sensing modalities—such as electromagnetic induction, ground-penetrating radar (GPR), and acoustic sensors—creates a multi-layered detection framework that overcomes the limitations of singular methods. This fusion not only improves the reliability of utility localization but also enables real-time validation of data, crucial for navigating complex urban environments. According to industry-leading research in Automation in Construction, multi-sensor fusion minimizes false positives and provides a holistic view of subsurface conditions, empowering contractors with actionable intelligence.

How can integrated sensor systems redefine safety protocols on underground construction sites?

By offering real-time hazard detection and predictive analytics, integrated sensor networks facilitate proactive safety measures, preventing accidental utility strikes and infrastructure damage. These systems can alert operators to potential issues before excavation, enabling immediate corrective actions and safeguarding personnel and assets. Advanced sensor integration, supported by AI-driven analytics, is rapidly becoming a standard in high-stakes urban projects, as highlighted in recent industry white papers. To stay ahead, professionals should explore comprehensive resources like Underground Infrastructure Magazine for case studies and technological reviews.

Harnessing 3D Geospatial Modeling for Precision Planning

The advent of high-resolution 3D geospatial mapping techniques, including LiDAR and photogrammetry, allows for detailed visualization of underground utility networks. These models facilitate collision avoidance, route optimization, and clash detection long before trenching begins, reducing costly rework and delays. The Journal of Geotechnical & Geoenvironmental Engineering underscores that integrating 3D GIS with sensor data enhances subsurface understanding, supporting safer and more efficient excavation planning.

Expert Insights on Underground Infrastructure Safety

Prioritize Multi-Modal Sensor Fusion

Integrating electromagnetic, GPR, and acoustic sensors with AI algorithms enhances utility detection accuracy, reducing risks and unforeseen delays in complex urban environments.

Leverage Real-Time Data Analytics for Proactive Safety

Employing real-time data analysis enables operators to identify potential utility conflicts early, optimizing trenching routes and safeguarding existing infrastructure.

Adopt 3D Geospatial Modeling for Precise Planning

Utilize LiDAR and photogrammetry to create detailed 3D models that facilitate clash detection, route optimization, and efficient project execution.

Implement Adaptive Hydrovac Solutions

AI-driven hydrovac systems respond dynamically to site conditions, minimizing damage and accelerating excavation processes while ensuring safety.

Stay Ahead with Emerging Technologies

Machine learning, robotics, and sensor fusion are set to redefine underground safety standards, making proactive hazard detection a standard industry practice.

Curated Resources for Deep Expertise

- Hydrovac Drilling White Papers: In-depth technical reports on hydrovac and vacuum excavation innovations.

- Automation in Construction Journal: Cutting-edge research on multi-sensor fusion and AI applications in underground mapping.

- Geospatial World Articles: Practical guides on implementing 3D GIS and LiDAR technologies for underground infrastructure projects.

- Underground Infrastructure Magazine: Case studies and industry insights on safety and technological advancements.

Final Perspective: Elevating Underground Safety and Precision

Advanced trenching, borehole, and hydrovac methods form the backbone of resilient and precise underground utility mapping. Embracing these innovative strategies not only mitigates risks but also paves the way for smarter urban infrastructure development. Professionals committed to staying at the forefront should continuously explore emerging technologies and contribute their insights to industry dialogues, fostering a safer, more efficient underground construction landscape.