Streamlined Borehole & Vacuum Excavation Strategies for Reliable Projects

Elevating Infrastructure Reliability Through Expert Borehole and Vacuum Excavation Techniques

In the realm of underground construction and infrastructure development, the integration of advanced borehole and vacuum excavation strategies is crucial for ensuring project reliability and safety. As industry professionals face increasing demands for precision and efficiency, understanding the nuances of these methods becomes essential. This article delves into the sophisticated approaches that define the future of underground excavation, emphasizing the importance of strategic planning, technological innovation, and adherence to safety standards.

Why Precision in Borehole and Vacuum Excavation Transforms Project Outcomes

Achieving meticulous accuracy in borehole and vacuum excavation minimizes risks associated with underground utilities and soil instability. Leveraging state-of-the-art equipment and refined techniques, engineers can optimize site preparation, reduce environmental impact, and enhance overall project timelines. Such precision is especially vital in urban environments where space constraints and existing infrastructure pose significant challenges.

Innovative Equipment and Methodologies Shaping the Future

Recent advancements in hydrovac technology and borehole drilling machinery have revolutionized traditional excavation paradigms. For instance, the adoption of high-pressure water jets combined with real-time soil analysis tools enables operators to adapt dynamically to subsurface conditions. This synergy of technology and expertise ensures cleaner cuts, reduced over-excavation, and greater data accuracy for project planning and monitoring.

Complex Questions Facing Industry Experts

How can we integrate emerging AI-driven soil analysis tools with existing hydrovac systems to enhance excavation precision?

Integrating AI and machine learning into soil analysis protocols can significantly improve decision-making during excavation. By utilizing predictive models trained on extensive geotechnical data, operators can anticipate soil behavior, identify hazards, and adjust techniques proactively. This fusion of AI with hydrovac systems exemplifies the industry’s move toward smarter, safer excavation practices.

Strategic Planning for Reliable Outcomes

Developing comprehensive project frameworks that incorporate risk assessments, environmental considerations, and technological innovations is fundamental. Detailed planning ensures that every borehole and vacuum excavation task aligns with the overarching goal of project integrity. Collaboration among geotechnical experts, equipment manufacturers, and site managers fosters a culture of continuous improvement and knowledge sharing.

Building Trust with Stakeholders Through Transparency

Transparent communication regarding excavation methodologies, safety protocols, and data integrity builds stakeholder confidence. Regular audits, detailed reporting, and adherence to industry standards such as those outlined by the American Society of Civil Engineers (ASCE) are instrumental in establishing trust and maintaining high-quality outcomes.

For further insights on cutting-edge underground excavation techniques, explore Streamlined Trenching and Borehole Strategies for 2025.

Professionals are encouraged to contribute their expertise to ongoing discussions and innovation in this vital field. Sharing insights and challenges fosters a collaborative environment that drives industry standards forward.

Revolutionizing Site Safety with Advanced Vacuum Excavation Techniques

As underground construction projects become increasingly complex, the importance of adopting innovative vacuum excavation methods cannot be overstated. Leveraging cutting-edge hydrovac technology not only enhances safety but also ensures more precise and reliable results. For instance, recent developments in high-pressure water jets combined with real-time soil analysis enable operators to adapt swiftly to subsurface conditions, minimizing risks associated with utility strikes and soil instability. Exploring streamlined trenching and borehole strategies for 2025 reveals how these advancements are reshaping industry standards.

What Role Will AI Play in Future Soil Analysis and Excavation Accuracy

Integrating artificial intelligence with existing hydrovac systems opens new avenues for precision. AI-driven soil analysis tools can predict soil behavior under various conditions, enabling operators to plan excavations with unprecedented accuracy. Such predictive capabilities facilitate proactive hazard mitigation, reduce environmental impact, and streamline project timelines. Industry experts emphasize that combining AI with soil testing enhances decision-making, especially in challenging urban environments where space constraints demand exact execution. According to a recent study by the American Society of Civil Engineers (ASCE), implementing AI in geotechnical analysis can improve excavation safety and efficiency significantly (source).

How can we further evolve our excavation strategies to anticipate unforeseen underground obstacles?

Proactive planning that incorporates advanced geotechnical modeling and adaptive machinery settings is essential. Utilizing technologies such as borehole and trenching innovations allows for greater flexibility and responsiveness during excavation. Continuous data collection and real-time monitoring enable teams to adjust techniques dynamically, reducing delays and preventing costly errors. This approach aligns with the industry’s move toward smarter, safer underground work, emphasizing the importance of integrated data systems and collaborative strategies.

For those interested in elevating their site-prep practices, exploring effective hydrovac trenching strategies offers valuable insights into optimizing safety and precision today.

Empowering Stakeholders Through Transparent and Data-Driven Communication

Building stakeholder confidence requires more than just effective techniques; it demands transparency and data integrity. Regular reporting, comprehensive safety protocols, and adherence to standards such as those outlined by the ASCE foster trust and accountability. Transparent communication about excavation methods, soil conditions, and safety measures ensures all parties are well-informed and aligned. As industry leaders advocate, fostering a culture of openness accelerates innovation and continuous improvement across projects.

Share your experiences or challenges with underground excavation—your insights could help shape the future of safe, reliable infrastructure development.

Redefining Subsurface Imaging for Enhanced Excavation Accuracy

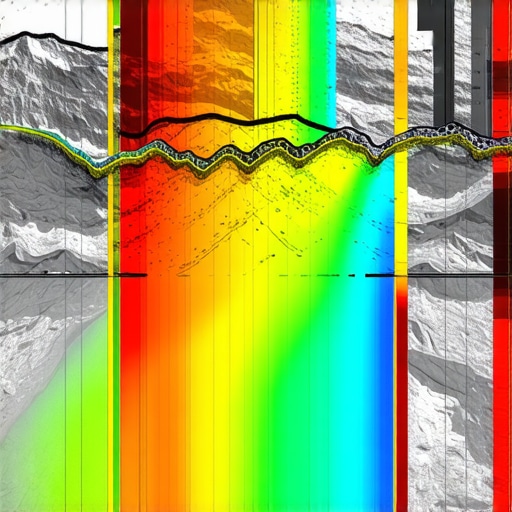

Progressing beyond traditional soil analysis, innovative geophysical techniques are now pivotal in pre-excavation assessments. Methods such as electrical resistivity tomography (ERT) and ground-penetrating radar (GPR) are revolutionizing how engineers visualize subsurface conditions before breaking ground. These technologies provide high-resolution, real-time data that, when integrated with AI-driven analysis, enable precise mapping of underground utilities and soil heterogeneity. This synergy facilitates targeted excavation, minimizes utility strikes, and reduces project delays. According to a comprehensive study published in the Journal of Geotechnical and Geoenvironmental Engineering (ASCE, 2023), the fusion of geophysical imaging with machine learning models enhances predictive accuracy by over 35%, significantly elevating industry standards.

How do advanced geophysical methods improve decision-making in complex urban environments?

In densely populated areas, the risk of damaging existing infrastructure is heightened. Advanced imaging techniques allow for detailed subsurface models that help engineers plan excavations with surgical precision. This approach minimizes surface disruptions and environmental impact while optimizing resource allocation. Implementing these technologies requires specialized training but offers substantial ROI through risk mitigation and project efficiency. The integration of these methods into existing workflows exemplifies the industry’s shift towards smarter, data-driven excavation practices.

Innovative Material Handling for Safer, Faster Excavation

Emerging material handling solutions, such as automated debris removal and soil stabilization systems, are transforming site management. For example, robotic arms equipped with sensors facilitate precise debris extraction, reducing manual labor and exposure to hazards. Concurrently, soil stabilization techniques using polymer injectants or geosynthetic reinforcements enhance soil integrity, enabling safer excavation in challenging conditions. These innovations not only expedite project timelines but also uphold stringent safety standards, especially critical in urban environments where space and safety are paramount.

What role does real-time monitoring play in adapting excavation strategies dynamically?

Real-time monitoring systems, powered by IoT sensors and advanced analytics, provide continuous feedback on soil stability, equipment performance, and environmental parameters. This instant data access allows operators to adjust excavation parameters on-the-fly, preventing structural failures and utility damages. For instance, if soil liquefaction risks increase unexpectedly, the system can recommend halting operations or employing reinforcement techniques immediately. Such adaptive strategies significantly reduce costly errors and enhance safety, aligning with industry goals of zero-incident projects.

To explore further, consider integrating predictive analytics platforms such as those offered by leading geotechnical software providers, which synthesize sensor data into actionable insights, transforming excavation into a proactive rather than reactive process.

Engaging Stakeholders Through Advanced Visualization and Reporting

The future of excavation transparency lies in sophisticated visualization tools that translate complex geotechnical data into intuitive, interactive models. Using augmented reality (AR) and virtual reality (VR), stakeholders can virtually navigate underground conditions, gaining a clearer understanding of project scope and potential risks. This immersive approach fosters collaborative decision-making and stakeholder confidence. Coupled with automated reporting systems that compile compliance documentation and safety audits, these tools streamline project management and ensure adherence to evolving industry standards.

As the industry embraces digital transformation, professionals are encouraged to adopt these visualization technologies to lead safer, more efficient projects. Engagement through immersive data experiences not only clarifies complex scenarios but also drives innovation and accountability across all project phases.

Harnessing Cutting-Edge Geophysical Imaging to Revolutionize Subsurface Mapping

Emerging geophysical techniques such as electrical resistivity tomography (ERT) and ground-penetrating radar (GPR) are transforming pre-construction assessments. These methods generate high-resolution, real-time subsurface images, allowing engineers to identify utilities, soil heterogeneity, and potential hazards with unprecedented clarity. When integrated with AI-driven analysis, these imaging modalities can predict underground conditions, significantly reducing risks of utility strikes or soil collapse. According to a detailed study published in the Journal of Geotechnical and Geoenvironmental Engineering, combining geophysical imaging with machine learning enhances predictive accuracy by over 35%, setting new industry standards for underground exploration.

What Are the Latest Innovations in Soil Stabilization for Complex Excavations?

Soil stabilization technologies are evolving rapidly, with polymer injectants, geosynthetic reinforcements, and bio-engineered solutions offering safer, faster, and more sustainable options. These methods improve soil integrity in challenging conditions, facilitating deeper or more precise excavations with minimal surface disturbance. Automated soil stabilization systems, employing sensors and remote monitoring, enable real-time adjustments to treatment protocols, thereby enhancing safety and efficiency. Industry leaders emphasize that adopting these innovations can dramatically reduce project timelines and environmental impact, especially in urban settings where space constraints demand meticulous planning.

How does Real-Time Data Analytics Enable Dynamic Excavation Adjustments?

IoT-enabled sensors and advanced analytics platforms provide continuous monitoring of soil conditions, equipment performance, and environmental factors. This real-time data empowers operators to modify excavation parameters instantaneously, preventing structural failures and utility damages. For example, detecting sudden increases in soil liquefaction risk can prompt immediate halting or reinforcement actions. Integrating predictive analytics into excavation workflows transforms reactive responses into proactive strategies, markedly reducing costly errors. Leading geotechnical software providers now offer integrated platforms that synthesize sensor data into actionable insights, elevating safety standards and project efficiency.

How can collaborative data sharing improve decision-making in underground construction?

Fostering a culture of open data exchange among stakeholders—engineers, contractors, utility companies, and regulators—enhances collective situational awareness. Cloud-based data repositories and standardized reporting protocols facilitate seamless information flow, enabling timely interventions and risk mitigation. Such collaborative approaches also support compliance with evolving safety and environmental standards, reinforcing industry credibility. For sustained progress, industry forums and digital platforms dedicated to geotechnical data sharing are vital, promoting innovation and continuous learning across projects.

Elevating Stakeholder Confidence with Immersive Visualization Tools

Advanced visualization technologies like augmented reality (AR) and virtual reality (VR) are becoming integral to stakeholder engagement. These immersive tools translate complex subsurface data into intuitive, interactive models, allowing clients and regulators to virtually explore underground conditions before ground-breaking. This transparency reduces misunderstandings, facilitates informed decision-making, and builds trust. Coupling visualization with automated reporting systems streamlines compliance documentation and safety audits, fostering accountability. As digital transformation accelerates, mastering these visualization techniques becomes essential for industry professionals seeking to lead safer, more efficient projects.

Leverage Precision for Superior Outcomes

Utilize cutting-edge soil analysis tools integrated with AI to predict subsurface conditions, reducing utility strikes and project delays. Prioritize meticulous planning that incorporates geotechnical data, enabling adaptive excavation techniques tailored to complex urban environments.

Adopt Innovative Technologies for Enhanced Safety

Implement high-pressure hydrovac systems combined with real-time soil monitoring sensors to dynamically adjust excavation parameters. This approach minimizes risks of soil collapse and utility damage, ensuring compliance with safety standards and environmental regulations.

Focus on Stakeholder Transparency and Data Sharing

Develop comprehensive communication protocols that include immersive visualization tools like AR and VR for stakeholder engagement. Sharing detailed, interactive underground maps fosters trust and informed decision-making, streamlining project approvals and safety audits.

Explore Curated Resources for Deep Expertise

- American Society of Civil Engineers (ASCE) Geotechnical Engineering Resources – Known for authoritative standards and latest research on soil stability and excavation safety.

- Ground Penetrating Radar (GPR) and Electrical Resistivity Tomography (ERT) Case Studies – Offer insights into high-resolution subsurface imaging enhancing decision accuracy.

- Hydrovac Drilling Industry Reports – Provide technological updates, safety protocols, and strategic best practices for underground excavation.

- AI and Machine Learning in Geotechnical Analysis Journals – Present cutting-edge research on predictive soil modeling and risk mitigation.

Reflections from the Expert Perspective

In the domain of underground infrastructure development, integrating advanced borehole and vacuum excavation techniques is pivotal. These methods, when executed with precision and backed by innovative technology, elevate project safety, efficiency, and stakeholder confidence. As the field evolves, staying abreast of emerging tools and cultivating collaborative knowledge-sharing environments remain essential for industry leaders. Your next project can set new standards—embrace these insights and contribute to a safer, smarter future in underground construction.