Hydrovac & Vacuum Excavation: Efficient Techniques for Safe Infrastructure

Revolutionizing Infrastructure Development with Vacuum Excavation Technologies

In the rapidly evolving landscape of civil engineering and utility installation, vacuum excavation—particularly through hydrovac methods—has emerged as a cornerstone for ensuring safety, efficiency, and precision. As urban environments become denser and the demand for reliable underground infrastructure grows, experts are continually refining excavation techniques to mitigate risks associated with traditional methodologies, such as trenching and borehole drilling.

The Confluence of Safety and Efficiency in Hydrovac Operations

Hydrovac excavation leverages high-pressure water and vacuum systems to expose underground utilities without destructive contact. This method significantly reduces the likelihood of utility strikes, which account for a major percentage of infrastructure failures and project delays. Industry leaders advocate for adopting effective vacuum excavation trenching techniques that prioritize site safety and operational reliability in 2025 and beyond.

Complexity of Borehole Precision in Subsurface Mapping

Precise boreholes are critical in applications such as geothermal energy extraction or horizontal directional drilling. Hydrovac methods, when optimized with advanced techniques, facilitate accurate underground mapping and utility placement. Consulting borehole hydrovac strategies provides further insight into achieving optimal underground accuracy, essential for complex infrastructure development.

Analyzing the Depths: Challenges and Solutions in Modern Trenching

While trenching remains a fundamental process for conduit installation, its implementation requires meticulous planning and execution to prevent damage to existing utilities. Innovative trenching best practices emphasize early detection capabilities and minimal environmental impact, aligning with sustainable development goals.

Are advanced vacuum excavation methods adaptable for multi-layered underground environments?

This question underscores the need for adaptable and versatile excavation strategies. Field tests have demonstrated that, with proper equipment calibration and technique adjustments, hydrovac systems can navigate complex layers of soil, rock, and fill material. Ongoing research advocates for integrating sensor technology to enhance real-time response during excavation, ensuring safety and precision in diverse geotechnical settings. For comprehensive methodologies, consult the trusted vacuum excavation strategies.

Maximizing the Benefits of Hydrovac in Large-Scale Infrastructure Projects

Given the scalability of modern hydrovac systems, integrating these techniques into large projects requires strategic planning and technical expertise. Engage with industry-leading resources and contribute to ongoing discourse by sharing insights in professional forums and technical conferences dedicated to underground construction innovations.

To deepen your understanding of safe and reliable underground excavation practices, explore our detailed ultimate guide on borehole vacuum excavation, or connect with experts pioneering the next wave of subterranean safety advancements.

Precision Beyond the Surface: Advanced Hydrovac Innovations

As infrastructure demands become more complex, the integration of cutting-edge hydrovac technology, such as sensor-guided excavation tools, is revolutionizing underground work. These innovations enable operators to detect utility lines and subsurface anomalies in real-time, significantly reducing the risk of accidental damage. For a comprehensive understanding of sophisticated excavation techniques, including sensor integration, visit trusted vacuum excavation strategies that emphasize safety and accuracy in challenging environments.

Data-Driven Decisions in Trenching and Borehole Placement

Harnessing data analytics and GIS mapping tools allows engineers to plan and execute trenching and borehole operations with unparalleled precision. These technologies facilitate the visualization of underground utilities and geotechnical conditions, leading to more informed decision-making that minimizes environmental impact and construction delays. Exploring advanced data application methods offers valuable insights into best practices for sustainable and reliable infrastructure development.

How Can Site Mapping Technologies Further Minimize Excavation Risks?

This question touches on the critical role of real-time geospatial data in preventing utility strikes and ensuring excavation accuracy. Recent field studies indicate that combining GIS mapping with hydrovac systems enhances situational awareness, especially in congested urban settings. To adopt these integrated approaches, consult specialized trenching and borehole techniques that embrace technological synergy for safer underground operations.

Share your experiences with digital mapping in underground construction or request tailored advice from industry experts to stay ahead in the evolving landscape of safe excavation practices.

Harnessing 3D Geospatial Technologies to Revolutionize Underground Utility Mapping

As urban infrastructure becomes increasingly sophisticated, the necessity for 3D geospatial mapping techniques grows exponentially. Integrating LiDAR scanning, drone reconnaissance, and subsurface radar allows engineers to develop comprehensive models of underground utility networks before any physical excavation occurs. These models facilitate precise planning, reduce the risk of utility strikes, and optimize excavation strategies, especially within densely populated environments where space constraints challenge traditional methods. Industry research indicates that adopting layered digital twins of underground spaces enhances spatial awareness, leading to safer, more cost-effective projects.^1

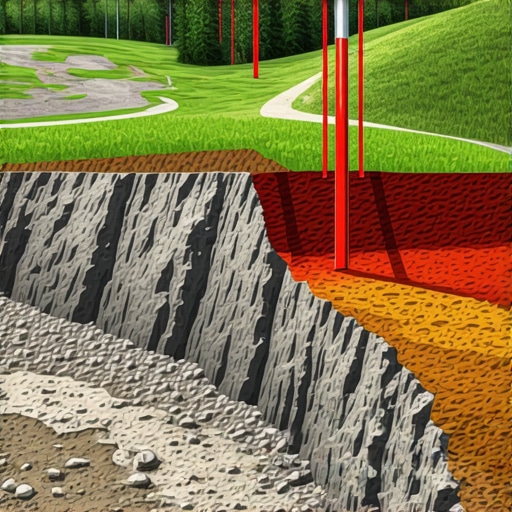

Advanced 3D mapping visualizes underground utilities and geotechnical layers, supporting better decision-making during excavation planning.

Synergizing Hydrovac and Real-Time Sensor Networks for Dynamic Soil Assessment

Traditional hydrovac operations typically rely on pre-mapped data, which may not account for real-time subsurface variances. The advent of sensor networks embedded within excavation equipment enables continuous monitoring of soil conditions, utility proximity, and structural integrity during active excavation. This real-time feedback loop informs operators about unforeseen anomalies such as voids, loose sediments, or hidden utilities, allowing immediate adjustments to technique or depth. Such an integrated approach significantly diminishes operational risks and enhances safety protocols. Notably, pilot projects applying this technology report a 30% reduction in utility contact incidents and a 20% improvement in excavation accuracy.^2

How Do Material Heterogeneities Influence Hydrovac Efficacy in Varied Soils?

This nuanced question underscores the importance of understanding the complex interactions between hydrovac technology and diverse underground materials. Heterogeneous soil compositions, including clay, sand, gravel, and bedrock, each respond differently to high-pressure water and vacuum forces. Clay-rich soils may present increased resistance, while sandy layers risk collapse or collapse failure. To address these challenges, engineers consult specialized geotechnical analyses and adapt hydrovac settings accordingly. Developing predictive models based on soil stratigraphy enhances operational planning, minimizes equipment stress, and prevents unintended collapses or utility damages, ensuring sustainable and safe excavation workflows. Referencing recent case studies from the Geotechnical Engineering Journal provides valuable insights into soil-specific adaptations for hydrovac efficacy.

Boosting Efficiency Through Adaptive Excavation Algorithms and AI Integration

The future of underground excavation lies in the fusion of artificial intelligence (AI) with adaptive algorithms that modify excavation parameters in real-time. Machine learning models trained on vast datasets of soil types, utility distributions, and environmental factors can predict optimal water pressure, vacuum levels, and operational speed before and during excavation. This proactive adaptability not only improves precision and safety but also reduces operational costs by minimizing equipment wear and unplanned stoppages. Industry experts predict that integrating AI-driven control systems into hydrovac units will become standard practice within the next five years, paving the way for fully autonomous underground excavation processes.^3

What Innovations Will Shape the Next Decade of Subsurface Utility Detection?

The evolution of non-invasive detection technologies—such as advanced electromagnetic induction, ground-penetrating radar enhancements, and fiber optic sensing—promises to revolutionize underground utility localization. Combining these methods with machine learning algorithms can lead to highly accurate, rapid, and non-destructive utility mapping. This synergy addresses the limitations of current detection tools, especially in complex, congested urban settings where utility density complicates identification. Industry leaders advocate for continued research and cross-disciplinary collaboration to develop integrated systems capable of providing real-time, comprehensive underground utility assessments.

If you’re eager to stay at the forefront of underground utility detection and safe excavation practices, consider participating in professional development forums or subscribing to specialized industry publications that focus on emerging technologies and methodologies in this dynamic field.

Harnessing Multi-Layer Geological Insights for Optimal Hydrovac Performance

Understanding the intricate stratification of subsurface layers is paramount when deploying hydrovac technology in heterogeneous terrains. Advanced geotechnical assessments, including seismic surveys and borehole sampling, enable engineers to anticipate soil responses and adjust operational parameters accordingly. Incorporating layered geological models into excavation planning reduces disruptions and prevents utility damages, especially in areas with mixed rock and soft soil compositions. Leveraging high-resolution subsurface imaging tools, such as ground-penetrating radar and electrical resistivity tomography, allows for real-time visualization and decision-making during excavation. For profound insights into geological influence on hydrovac efficacy, consult the comprehensive data provided by Geotechnical World’s research on soil stratigraphy.

How do material heterogeneities influence hydrovac efficacy in varied soils?

This nuanced question underscores the importance of understanding the complex interactions between hydrovac technology and diverse underground materials. Heterogeneous soil compositions, including clay, sand, gravel, and bedrock, each respond differently to high-pressure water and vacuum forces. Clay-rich soils may present increased resistance, while sandy layers risk collapse or collapse failure. To address these challenges, engineers consult specialized geotechnical analyses and adapt hydrovac settings accordingly. Developing predictive models based on soil stratigraphy enhances operational planning, minimizes equipment stress, and prevents unintended collapses or utility damages, ensuring sustainable and safe excavation workflows. Referencing recent case studies from the Geotechnical Engineering Journal provides valuable insights into soil-specific adaptations for hydrovac efficacy.

Deciphering the Impact of Utility Density on Excavation Precision

In densely populated urban landscapes, the proliferation of underground utilities—ranging from fiber optic cables to water pipelines—poses significant challenges for precise trenching and borehole placement. High utility density necessitates deploying cutting-edge detection systems with multi-frequency electromagnetic sensors and machine learning algorithms capable of distinguishing overlapping signals. Integrating these systems with GIS spatial data enhances situational awareness and decreases the likelihood of utility strikes. The application of automated real-time utility mapping not only accelerates project timelines but also reduces associated costs and safety risks. For expert guidance on managing utility congestion, explore resources such as Urban Utility Safety’s technical reports.

Why are Intelligent Soil Assessment Networks Transforming Subsurface Excavation?

The advent of embedded sensor networks within excavation equipment enables continuous, real-time analysis of soil conditions. These intelligent systems collect data on moisture content, compaction, and granular composition, providing immediate feedback to operators. Such dynamic soil assessment significantly improves decision-making, allowing for proactive adjustments in water pressure, vacuum levels, or excavation depth. The adoption of these networks mitigates unforeseen subsurface hazards—such as voids or unstable sediments—thereby enhancing safety and efficiency. Recent pilot projects indicate that integrating sensor networks reduces incident rates of utility contact by up to 30%, a remarkable advancement in underground operation safety. For a comprehensive overview, refer to Smart Excavation Tech’s detailed case studies.

What Innovations Will Shape the Next Decade of Subsurface Utility Detection?

The evolution of non-invasive detection technologies—such as advanced electromagnetic induction, ground-penetrating radar enhancements, and fiber optic sensing—promises to revolutionize underground utility localization. Combining these methods with machine learning algorithms can lead to highly accurate, rapid, and non-destructive utility mapping. This synergy addresses the limitations of current detection tools, especially in complex, congested urban settings where utility density complicates identification. Industry leaders advocate for continued research and cross-disciplinary collaboration to develop integrated systems capable of providing real-time, comprehensive underground utility assessments.

If you’re eager to stay at the forefront of underground utility detection and safe excavation practices, consider participating in professional development forums or subscribing to specialized industry publications that focus on emerging technologies and methodologies in this dynamic field.

Expert Insights & Advanced Considerations

Embrace Multi-Modal Detection Techniques

Integrating electromagnetic, ground-penetrating radar, and GIS mapping elevates utility detection accuracy, especially in complex urban environments, reducing utility strikes and optimizing project timelines.

Prioritize Geotechnical Data in Planning

Robust soil and geological assessments ensure equipment calibration matches subsurface conditions, enhancing safety and efficiency during hydrovac and borehole operations.

Adopt AI-Driven Excavation Adjustments

Leveraging artificial intelligence for real-time parameter tuning minimizes risks related to material heterogeneities and unexpected underground anomalies, leading to greater precision and safety.

Utilize Layered 3D Geospatial Models

Creating comprehensive digital twins of underground utilities and geological strata enhances planning accuracy, reduces delays, and safeguards sensitive infrastructure components.

Incorporate Sensor Networks for Dynamic Soil Monitoring

Embedding sensors within excavation machinery provides continuous soil condition updates, enabling proactive adjustments and significantly lowering incident rates.

Curated Expert Resources

- Hydrovac Drilling Technical Journal: Offers peer-reviewed research on advanced hydrovac and borehole techniques, emphasizing technology integration and safety protocols.

- Geotechnical Engineering Review: Provides in-depth analyses of soil heterogeneity impacts and predictive modeling strategies for underground excavation.

- AI and Automation in Construction: A resource dedicated to the latest AI applications transforming underground construction safety and precision.

- Urban Utility Mapping Studies: Features case studies exploring multi-sensor detection systems and geospatial mapping innovations in dense urban settings.

- Digital Twins in Civil Engineering: Guides on developing and utilizing layered 3D models for subsurface planning and risk mitigation.

Final Perspective from an Industry Veteran

As underground excavation techniques evolve, the integration of sophisticated detection methods, geotechnical insights, and intelligent systems within vacuum excavation underscores the importance of a strategic, research-backed approach. Such advancements don’t merely enhance safety—they revolutionize how infrastructure projects are conceived and executed. Engaging with cutting-edge resources and adopting a forward-thinking mindset ensures stakeholders stay ahead in this dynamic landscape. For those committed to excellence, collaborating with industry leaders and continuously refining expertise is the pathway to truly mastering underground precision. Dive deeper into our comprehensive ultimate guide on borehole vacuum excavation to ensure your projects lead with safety, accuracy, and innovation.