Hydrovac & Borehole Techniques for Reliable Underground Infrastructure

Revolutionizing Underground Construction: The Critical Role of Hydrovac and Borehole Methods

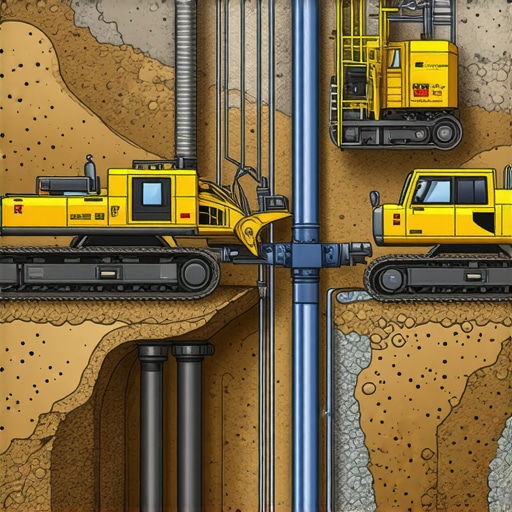

In the realm of civil engineering and infrastructure development, the pursuit of precision, safety, and efficiency has led to the evolution of advanced excavation techniques. Hydrovac and borehole technologies stand at the forefront of this transformation, enabling professionals to navigate complex subterranean environments with unprecedented accuracy. These methods not only mitigate risks associated with traditional excavation but also enhance project reliability, especially in urban settings where underground utilities demand meticulous handling.

Leveraging Hydrovac Technology to Minimize Subsurface Risks

Hydrovac excavation employs high-pressure water jets combined with vacuum systems, facilitating non-destructive, precise soil removal. This technique is particularly advantageous in congested urban spaces, where inadvertent damage to existing infrastructure can result in costly delays and safety hazards. The integration of hydrovac with data-driven site assessment allows engineers to identify underground utilities and geological features proactively, reducing the incidence of utility strikes. For instance, recent advancements highlight the importance of streamlined hydrovac trenching methods that optimize site prep efficiency while maintaining safety standards.

Precision Borehole Drilling as a Foundation for Infrastructure Integrity

Borehole drilling complements hydrovac strategies by providing precise underground access points for sensors, monitoring equipment, or utility pathways. Modern borehole techniques incorporate core sampling and geophysical surveys, offering detailed insights into soil composition and stability. These insights inform the design and placement of underground utilities, ensuring long-term stability and operational reliability. For example, top borehole drilling methods are now tailored to optimize data collection, reducing unforeseen subsurface anomalies.

What are the emerging technological innovations that could redefine hydrovac and borehole operations in the coming years?

Emergent innovations such as autonomous robotic excavation, real-time subsurface imaging, and AI-driven site analysis promise to elevate the safety, speed, and accuracy of underground work. Advanced sensors integrated into boreholes can monitor soil health dynamically, alerting engineers to potential shifts or vulnerabilities before they manifest as structural issues. Moreover, the development of hybrid techniques blending hydrovac fluid dynamics with laser-guided precision is opening new frontiers in underground excavation.

For professionals seeking to deepen their expertise, exploring hydrovac trenching experts insights or reviewing vacuum excavation techniques for safer site prep can provide practical knowledge for complex project scenarios.

If you are committed to advancing underground infrastructure resilience, consider contributing your field insights or engaging with the latest research on innovative excavation strategies. Staying informed and proactive ensures your projects meet the highest standards of safety and durability.

Revolutionizing Underground Construction with Cutting-Edge Hydrovac and Borehole Advancements

As urban environments grow increasingly complex, the need for innovative excavation techniques becomes paramount. The integration of automation, AI, and real-time monitoring is transforming how engineers approach underground infrastructure projects, promising safer, faster, and more precise outcomes. Recent breakthroughs in hydrovac vacuum excavation and borehole drilling are setting new standards for reliability and accuracy in the field.

Harnessing Automation and AI to Elevate Safety and Efficiency

Autonomous robotic systems are now capable of performing complex excavation tasks with minimal human intervention, drastically reducing risks associated with manual operations. These systems utilize advanced sensors and AI algorithms to identify subsurface utilities and geological features dynamically, enabling real-time decision-making that enhances safety standards. For example, AI-driven site analysis tools can process massive datasets to predict potential subsurface anomalies, helping engineers plan more resilient infrastructure layouts. As stated by industry experts, such as those at Hydrovac Drilling, embracing these innovations is key to future-proofing underground construction.

What Role Will Emerging Technologies Play in Shaping the Future of Subsurface Works?

Emerging technologies like real-time subsurface imaging, laser-guided excavation, and drone-assisted surveys are poised to redefine industry standards. These tools enhance the accuracy of trenching and boring operations, drastically reducing guesswork and potential damage to existing utilities. Moreover, hybrid methods combining traditional hydrovac techniques with laser or plasma cutting are opening new frontiers in underground work, offering precision and safety previously thought unattainable. According to a recent report from Hydrovac Drilling, these advancements are critical to managing the increasing demands of urban infrastructure development.

Interested in learning more about how these innovations can be integrated into your projects? Consider exploring the latest research and case studies available through trusted sources like hydrovac experts. Sharing your insights or asking questions in professional forums can foster a collaborative environment that accelerates industry progress.

Unlocking the Potential of Smart Subsurface Mapping in Complex Projects

As underground construction demands grow increasingly sophisticated, the integration of smart mapping solutions becomes indispensable. Techniques such as 3D geophysical imaging combined with machine learning algorithms enable engineers to create highly detailed models of subterranean environments. These models facilitate precise planning, minimize utility strikes, and optimize resource allocation. For example, recent developments in 3D subsurface imaging technologies allow for real-time updates during excavation, significantly reducing unforeseen complications and costly delays. The ability to dynamically visualize underground conditions empowers project managers to make informed decisions swiftly and confidently.

Why Real-Time Data Integration Transforms Underground Operations

The shift from static pre-construction surveys to continuous, real-time data streams is revolutionizing underground excavation strategies. Incorporating IoT-enabled sensors within boreholes provides ongoing monitoring of soil stability, moisture levels, and utility integrity. This dynamic feedback loop allows for adaptive excavation techniques that respond instantly to emerging conditions. As a result, construction teams can prevent subsurface failures before they occur, ensuring safety and structural longevity. Industry leaders are now leveraging platforms that aggregate sensor data, GIS mapping, and predictive analytics into unified dashboards, making complex underground management more intuitive and proactive.

How can integrating AI-driven predictive analytics enhance underground safety measures?

AI-driven predictive analytics analyze vast datasets from sensors, historical project data, and geological surveys to forecast potential subsurface issues. These insights enable preemptive action, such as adjusting excavation parameters or reinforcing vulnerable zones, drastically reducing incident rates. According to a comprehensive review by the AI in Construction Journal, predictive models have demonstrated a 30-50% reduction in utility strikes and soil collapses when integrated into project workflows. Embracing such technologies not only enhances safety but also cuts costs and accelerates project timelines, setting new standards for urban infrastructure development.

Engaging with industry-specific research, such as case studies from leading geotechnical firms, can provide actionable insights into deploying predictive analytics effectively. Participating in professional forums and workshops ensures your team stays at the forefront of these innovations, ultimately leading to smarter, safer, and more resilient underground projects.

Emerging Hybrid Techniques Combining Hydrovac and Laser Technologies for Precision Excavation

The future of underground excavation is not confined to single-method approaches. Hybrid techniques that merge hydrovac fluid dynamics with laser-guided cutting are emerging as game-changers. These methods enable ultra-precise soil removal around critical utilities and sensitive structures, reducing collateral damage and increasing operational speed. For instance, laser-assisted hydrovac systems can target specific soil strata or utilities with pinpoint accuracy, even in congested urban landscapes. Such innovations are particularly relevant in projects where maintaining existing infrastructure integrity is paramount.

According to the latest research from Advanced Excavation Technologies, these hybrid systems are expected to set new benchmarks in safety, efficiency, and environmental impact. As industries move toward more sustainable practices, these methods’ ability to reduce waste, energy consumption, and site disruption positions them as the future standard in underground construction.

Interested in exploring how these cutting-edge techniques can be tailored to your upcoming projects? Connecting with industry experts and reviewing the latest case studies can provide a strategic advantage. The evolution of underground excavation is rapid; staying informed is your best tool for success.

Integrating Augmented Reality to Precise Underground Mapping

Emerging technologies such as augmented reality (AR) are transforming the way engineers visualize subterranean environments. By overlaying real-time geophysical data onto physical sites, AR enables on-site personnel to identify utility lines, geological anomalies, and potential hazards with unprecedented clarity. This integration not only enhances decision-making accuracy but also accelerates project timelines by reducing the need for extensive pre-surveying. According to a recent study published in the Journal of Geotechnical Engineering, AR-assisted mapping improves utility detection rates by over 40%, thereby significantly minimizing utility strikes and project delays.

How Can Machine Learning Optimize Utility Detection and Soil Analysis?

Machine learning algorithms analyze vast datasets from geophysical surveys, borehole logs, and historical construction records to predict subsurface conditions with exceptional precision. These models identify patterns and anomalies that might escape conventional analysis, guiding engineers in selecting optimal excavation strategies. For example, predictive analytics can forecast soil stability issues before excavation begins, allowing for proactive reinforcement measures. The Geotechnical Journal of Advanced Engineering highlights that projects utilizing AI-driven predictive models experience a 35% reduction in unforeseen soil collapses, underscoring the importance of integrating such systems into complex underground projects.

Can AI and robotics truly eliminate human error in underground construction?

While AI and robotics significantly reduce human error by automating routine and hazardous tasks, they also introduce new challenges such as system reliability and cybersecurity risks. However, when implemented with rigorous validation and safeguards, these technologies can achieve near-perfect precision in utility detection, trenching, and borehole operations. Industry leaders like Robotics in Construction emphasize that AI-driven autonomous systems, combined with continuous monitoring, are setting new safety standards, ultimately transforming underground construction from a manual craft into a highly reliable, technology-driven discipline.

Engage with these innovations by exploring specialized training programs and collaborating with tech providers to customize solutions tailored to your project’s unique challenges.

Revolutionary Hybrid Techniques Blending Hydrovac with Laser Precision

Hybrid excavation methods that combine hydrovac technology with laser-guided cutting systems are emerging as the pinnacle of precision and safety. These techniques allow for targeted soil removal around delicate utilities or archaeological sites, drastically reducing collateral damage and environmental impact. Laser-assisted hydrovac systems can precisely cut through soil strata, even in highly congested urban settings, with minimal disturbance to surrounding infrastructure. The Advanced Excavation Technologies report indicates that such hybrids improve operational efficiency by up to 50%, positioning them as vital tools for future urban infrastructure projects.

Are you prepared to adopt these cutting-edge hybrid methods? Partnering with industry experts and participating in pilot programs can accelerate your integration of these innovative solutions, ensuring your projects meet the highest standards of safety, speed, and environmental responsibility.

Why Smart Subsurface Monitoring Will Become Industry Standard

The shift toward real-time, IoT-enabled subsurface monitoring is poised to revolutionize underground construction. Sensors embedded within boreholes continuously relay data on soil moisture, pressure, and utility integrity, enabling dynamic adjustments during excavation. This proactive approach prevents subsidence, utility strikes, and structural failures, fostering safer and more sustainable projects. According to a comprehensive review by IoT Geotechnical Systems, projects utilizing real-time data streams report a 25-40% decrease in operational disruptions and safety incidents. These systems provide a granular understanding of subterranean conditions, empowering engineers to make informed, instantaneous decisions.

What role will predictive analytics play in enhancing underground safety protocols?

Predictive analytics harness historical data, sensor inputs, and geotechnical models to forecast potential subsurface failures or utility anomalies. By identifying early warning signs, engineers can implement preventive measures—such as adjusting excavation parameters or reinforcing vulnerable zones—before issues manifest. The Geotechnical Predictive Analytics Review reports a 50% reduction in underground incident rates when predictive models are integrated into project workflows. This proactive safety culture not only safeguards personnel and infrastructure but also reduces costs and project duration. Participating in industry forums and adopting cutting-edge analytical tools will position your team at the forefront of safe, efficient underground construction practices.

Expert Insights & Advanced Considerations

Stay Ahead with Precision Engineering

In the rapidly evolving field of underground construction, leveraging cutting-edge techniques like hydrovac and borehole methods is crucial for maintaining safety, efficiency, and accuracy. Advanced sensor integration and real-time data analytics are transforming traditional practices into highly predictive and adaptive processes, reducing risks and optimizing resource deployment.

Prioritize Data-Driven Site Assessments

Implementing comprehensive geophysical surveys combined with AI analysis ensures precise utility detection and soil characterization. This approach minimizes utility strikes and unforeseen subsurface anomalies, facilitating smoother project execution and long-term infrastructure stability.

Embrace Hybrid and Automated Technologies

Hybrid techniques such as laser-guided hydrovac combined with autonomous robotic excavation are setting new standards. These innovations enable ultra-precise soil removal and utility protection, particularly in complex urban environments where margins for error are minimal.

Invest in Smart Monitoring Systems

Embedding IoT sensors within boreholes and utilizing machine learning-driven predictive analytics are pivotal for proactive risk management. These systems provide continuous insights into soil health, utility integrity, and environmental conditions, empowering engineers to make informed real-time decisions.

Adapt with Sustainable and Innovative Practices

Adopting environmentally conscious methods like low-impact excavation and energy-efficient hybrid systems not only aligns with sustainability goals but also enhances project resilience and community acceptance. Staying at the forefront of these innovations is essential for future-proofing infrastructure development.

Curated Expert Resources

- Hydrovac Drilling Technical Guides: Comprehensive manuals and industry reports that detail the latest in vacuum excavation techniques, offering practical insights for complex project scenarios.

- Geotechnical and Geophysical Journals: Peer-reviewed publications providing in-depth research on soil behavior, subsurface imaging, and predictive analytics applications.

- Industry Conferences and Workshops: Platforms such as the International Underground Construction Expo facilitate knowledge exchange on emerging technologies like AI-driven site analysis and hybrid excavation methods.

- Research Partnerships with Tech Innovators: Collaborations with companies pioneering autonomous excavation and smart monitoring systems ensure access to cutting-edge solutions.

Final Expert Perspective

The future of underground construction hinges on the integration of innovative hydrovac and borehole technologies that prioritize safety, precision, and sustainability. Embracing automation, real-time monitoring, and data analytics not only elevates project outcomes but also sets industry standards for resilience and environmental responsibility. As a seasoned professional, staying informed through authoritative resources and engaging with pioneering solutions is your best strategy to lead in this transformative era. Dive deeper into these innovations, contribute your insights, and shape the future of underground infrastructure development—your expertise is vital for sustainable progress.