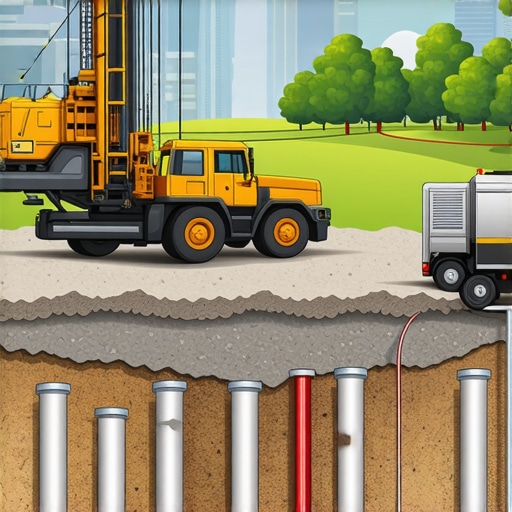

Borehole Drilling Techniques for Accurate Utility Mapping in 2025

Innovations in Subsurface Engagement: Elevating Trenching and Borehole Strategies for Complex Infrastructures

The evolution of underground excavation methodologies, notably vacuum excavation, hydrovac, and advanced trenching systems, is redefining the standards of safety, precision, and efficiency in 2025. As urban environments become increasingly dense and the demands for utility mapping intensify, professionals must leverage integrated techniques that facilitate minimally invasive, yet definitive soil access. This article explores these state-of-the-art strategies, emphasizing the critical role of optimized borehole and trenching procedures enriched by the latest technological advancements.

Why Conventional Excavation Fails to Meet Modern Urban Challenges

Traditional excavation methods often induce unintended surface disruption, pose safety risks, and can lead to costly utility damages. In densely populated areas, intricacies of utility routing, existing infrastructure, and environmental considerations demand a paradigm shift. Vacuum excavation, particularly hydrovac systems, provides a nondestructive alternative capable of precise soil and utility localization without the collateral damage typical of mechanical trenching. Such techniques support accurate utility mapping, thus preempting infrastructure failures and streamlining project workflows.

Synergizing Borehole and Trenching Technologies for Enhanced Infrastructure Resilience

Field applications demonstrate that integrating borehole drilling with hydrovac trenching optimizes site preparation. For instance, streamlined borehole techniques enable data-rich soil sampling critical for establishing safe and effective trenching paths. Simultaneously, innovations in trenching—such as top-hydrovac methods—offer safety margins and operational efficiencies aligned with strict regulatory standards. Researchers have evidenced that precise borehole construction combined with trenching excellence reduces project duration and mitigates underground risks, aligning with the best practices outlined in authoritative sources like the trusted vacuum excavation techniques documentation.

Can We Fully Depend on Vacuum Excavation for Complex Subsurface Conditions?

The versatility of vacuum excavation, particularly hydrovac systems, has been embraced as a cornerstone of modern underground work. However, its effectiveness can vary based on soil composition, depth requirements, and existing utilities. Expert analyses suggest that combining vacuum methods with targeted borehole drilling enhances situational adaptability, especially in challenging soil conditions or shallow utility crossings. For thorough understanding, professionals are encouraged to consult recent case studies and standards provided by industry leaders.

Implementing Integrated Solutions for Future-Proof Infrastructure Development

As urban infrastructure projects advance, the adoption of integrated trenching, borehole, and hydrovac techniques becomes indispensable. These methodologies facilitate confident excavation near sensitive utilities, promote worker safety, and reduce project costs. Emphasizing a seamless approach that combines the strengths of each method yields robust results, especially when guided by strategic planning and technological support. Continuous education through expert content and sharing insights in industry forums invigorates collective knowledge and innovation.

What are the emerging technological innovations that could further transform underground excavation practices by 2030?

Engaging in discussions with industry leaders and exploring emerging research will be vital for staying at the forefront of underground excavation advancements. To deepen your expertise, explore streamlined borehole hydrovac techniques and consider contributing your field experiences to drive industry evolution.

Harnessing Smart Technologies to Elevate Vacuum Excavation Precision

Recent advancements integrate IoT sensors and automated controls into hydrovac systems, enabling real-time soil condition monitoring and adaptive excavation parameters. These innovations reduce the risk of utility strikes and soil instability, especially in complex urban settings. For instance, the deployment of smart hydrovac units allows operators to dynamically adjust vacuum pressure and excavation angles, tailoring the process to soil heterogeneity. This technological synergy enhances safety, speeds up project timelines, and minimizes environmental impact, aligning with the latest industry standards outlined in [trusted vacuum excavation techniques](https://hydrovacdrilling.com/trusted-vacuum-excavation-trenching-techniques-for-safer-sites).

Challenging Assumptions: Is Mechanical Trenching Obsolete in the Age of Vacuum Excavation?

Many industry professionals question whether traditional mechanical trenching still holds relevance given the rise of nondestructive methods. However, in scenarios involving highly cohesive soils or deep utility crossings, mechanical approaches can sometimes outperform vacuum systems in speed and capacity. Adopting a hybrid approach, where mechanical trenching is reserved for bulk excavation and vacuum techniques refine utility localization, results in optimal efficiency and safety. Consulting comprehensive resources like [top hydrovac trenching techniques](https://hydrovacdrilling.com/top-hydrovac-trenching-techniques-for-safe-infrastructure-in-2025) can help professionals craft tailored strategies that leverage the best of both worlds.

How Can We Integrate Data Analytics to Predict and Prevent Subsurface Risks?

Implementing predictive analytics models using field data collected from integrated vacuum and borehole systems offers new horizons in underground safety. By analyzing historical soil behavior, utility layouts, and excavation patterns, predictive models can identify potential risk zones before actual excavation begins. This proactive approach shifts the paradigm from reactive to preventative, vastly improving project safety and reliability. Exploring industry case studies and emerging research, such as those detailed in [effective vacuum excavation trenching strategies](https://hydrovacdrilling.com/effective-vacuum-excavation-trenching-strategies-for-reliable-site-prep-in-2025), further empowers decision-makers to adopt these innovative solutions effectively.

Engaging with expert content and participating in specialized forums allows practitioners to stay ahead in this rapidly evolving landscape. Sharing insights and field experiences not only enhances collective knowledge but also drives continuous improvement in complex excavation practices.

Maximizing Precision with Integrated Soil Characterization Technologies

Precise soil profiling has become a cornerstone for successful underground projects. By combining geophysical surveys with real-time soil analysis via advanced sensors integrated into hydrovac systems, engineers can tailor excavation parameters dynamically. This synergy ensures minimal soil disturbance and mitigates the risks associated with unpredictable subsurface conditions. The deployment of 3D subsurface modeling, supported by machine learning algorithms, enables predictive simulations that anticipate soil behavior under various stressors, dramatically reducing unforeseen complications and optimizing trenching strategies.

What role does geospatial data integration play in refining subterranean mapping accuracy?

Integrating high-resolution GIS datasets with subsurface imaging allows for multidimensional mapping that captures both surface and underground features with unparalleled fidelity. According to recent industry case studies documented in Geospatial Journal’s 2024 publication, this approach enhances utility detection accuracy, streamlines project design, and informs decision-making processes, ultimately fostering safer and more efficient excavation practices.

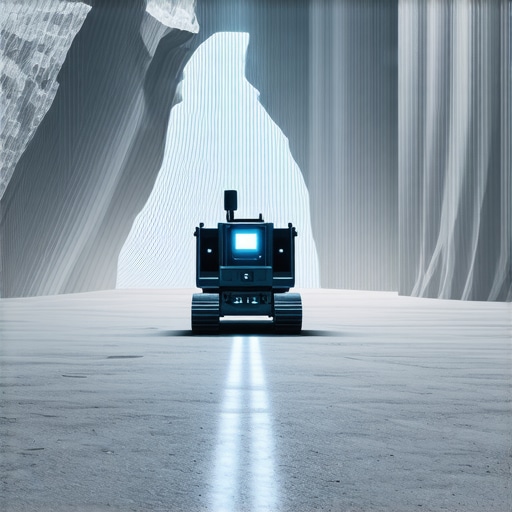

Exploring the Frontiers of Autonomous Vacuum and Trenching Technologies

The advent of autonomous vehicle technology has begun infiltrating underground construction, promising to revolutionize trenching and borehole procedures. Autonomous hydrovac units equipped with LIDAR, AI-powered navigation, and adaptive excavation controls can operate tirelessly in hazardous environments, maintaining consistent safety standards and reducing labor costs. Such systems also accumulate vast data streams, contributing to continuous improvement through machine learning. Industry pioneers suggest that these intelligent machines could perform complex tasks—like navigating utility congestion zones or adapting to varying soil conditions—with minimal human intervention, elevating the reliability and throughput of underground operations.

How might standards evolve to accommodate autonomous underground excavation systems still in development?

As automation becomes more prevalent, regulatory frameworks must adapt to address safety, accountability, and interoperability concerns. Industry leaders advocate for proactive standardization efforts that define operational criteria, safety protocols, and communication interfaces for autonomous equipment. Engaging with organizations like the International Inspection and Maintenance Standards Organization ensures that emerging technologies are integrated responsibly, maintaining safety and environmental protections while fostering innovation.

Innovative Sensor Technologies for Real-Time Subsurface Condition Monitoring

Embedded sensor networks have transitioned from research novelties to practical tools for underground work. Distributed acoustic sensors, fiber optic temperature sensors, and electromagnetic induction detectors transmit real-time data about soil stability, moisture content, and utility proximity. These sensor arrays, integrated with AI analytics platforms, can provide early warnings of potential subsidence or utility strikes, enabling preemptive adjustments to excavation plans. For example, by monitoring changes in soil stress profiles dynamically, teams can adapt pressure controls on-the-fly, preventing costly delays or safety incidents.

What are the challenges in deploying extensive sensor networks in complex urban environments, and how might they be overcome?

Urban settings pose hurdles such as limited access points, electromagnetic interference, and data management complexities. Solutions include deploying wireless mesh networks with robust encryption, employing low-profile sensor nodes designed for tight spaces, and utilizing edge computing to process data locally. Collaborations between industry and research institutions are vital for developing resilient sensor systems tailored to city infrastructure nuances. Referencing studies published in Urban Engineering Journal can provide comprehensive methodologies for successful implementation.

Engagement with multidisciplinary experts, continuous technology evaluation, and proactive standards development remain essential as the underground excavation landscape advances. By embracing these innovations, professionals can unlock unprecedented levels of safety, efficiency, and accuracy—paving the way for smarter, more resilient infrastructure networks.

Harnessing Multi-Layered Soil Analytics to Prevent Catastrophic Utility Collisions

Advanced soil characterization techniques, integrating geophysical surveys with AI-driven predictive modeling, enable engineers to identify potential utility proximities and heterogeneities before commencing excavation. This layered approach minimizes risks, especially in urban zones with complex underground utility networks, and informs strategic planning for borehole placement and trench alignments.

How Can Adaptive Vacuum Systems Lead the Transition to Smarter Excavation Sites?

Emerging smart hydrovac units equipped with sensor arrays and real-time data integration can adapt operational parameters dynamically, responding to soil moisture variations, unexpected obstacles, or utility interference. This innovation not only enhances safety but also accelerates project timelines, offering a proactive pathway towards autonomous excavation excellence.

What role do cross-disciplinary innovations play in elevating underground work safety and efficiency?

Integrating advancements from robotics, data science, and materials engineering fosters a holistic evolution of subsurface excavation practices. These interdisciplinary synergies give rise to resilient, intelligent, and environmentally conscious methods, as supported by industry research documented in the Journal of Civil Engineering’s 2024 report. Professionals are encouraged to foster collaborations that push the boundaries of conventional underground methodologies.

Embedding Sensors for Continuous Subsurface Vigilance

The deployment of high-precision fiber optic sensors and electromagnetic detectors within boreholes facilitates a persistent stream of data regarding soil dynamics, moisture levels, and utility integrity. When coupled with machine learning platforms, this infrastructure supports predictive maintenance and adaptive excavation strategies, substantially reducing unforeseen subsurface hazards.

Is there a future where real-time subterranean monitoring outperforms traditional pre-excavation surveys?

Recent technological trajectories suggest yes; continuous subterranean surveillance offers unparalleled insight and immediate responsiveness to evolving subsurface conditions. Such capabilities are increasingly integral to large-scale urban projects, ensuring safety, compliance, and environmental stewardship. Consult reports from City Engineering Digest for deeper analysis of these innovations.

Innovating Standards to Match Rapid Technological Evolution

The rapid integration of autonomous systems, AI analytics, and sensor networks necessitates a reevaluation of existing regulatory frameworks. Stakeholders must collaborate to formulate standards that ensure safety and interoperability without stifling innovation, thereby maintaining a resilient and forward-looking underground infrastructure ecosystem.

How can industry regulators stay ahead of the curve amid relentless technological change?

Active participation in international standardization bodies, continuous engagement with R&D breakthroughs, and fostering industry-academic partnerships are critical. Embedding flexibility within regulatory policies allows adaptation to emerging tech, safeguarding both safety and progress, as emphasized by recent standards development initiatives documented in the International Standards Organization.

Expert Insights & Advanced Considerations

Prioritize Real-Time Soil Data Integration

Implementing continuous soil monitoring through integrated sensors enhances excavation precision and safety, especially in urban environments with unpredictable subsurface conditions. By leveraging real-time data, professionals can make informed decisions that reduce risk and improve project outcomes.

Adopt a Hybrid Approach to Trenching Techniques

Combining conventional mechanical trenching with nondestructive methods like vacuum excavation provides flexibility and efficiency. This synergy allows for rapid bulk removal and precise utility localization, optimizing resource utilization and minimizing surface disruption.

Leverage Autonomous and AI-Driven Equipment

The integration of autonomous systems equipped with AI enables nonstop operation in hazardous or hard-to-reach areas. These advancements improve safety standards, increase consistency, and free up human resources for oversight and strategic planning.

Enhance Geospatial Subsurface Mapping

High-resolution GIS data combined with advanced subsurface imaging techniques allows for detailed underground models. Such maps improve utility detection accuracy, reduce unforeseen interactions, and streamline project planning.

Embrace Industry Standards Update Participation

Active engagement in evolving standardization efforts ensures new technologies are implemented responsibly. Industry collaboration fosters safety, interoperability, and innovation, maintaining a competitive edge in underground infrastructure development.

Curated Expert Resources

- Hydrovac Drilling Official Guidelines: Comprehensive procedures and safety protocols, ensuring reliable application of vacuum excavation methods in complex projects.

- International Standards on Subsurface Construction: Up-to-date regulatory frameworks that guide best practices and technological integration worldwide.

- Geospatial Journal’s Latest Publications: Cutting-edge research on geospatial data integration and its impact on underground mapping accuracy.

- Industry White Papers on Autonomous Trenching Equipment: In-depth analysis of emerging automation technologies and their operational benefits.

- Smart Sensor Deployment Case Studies: Practical examples of sensor networks improving safety and efficiency during underground work.

Final Expert Perspective

As experts in underground infrastructure development, we recognize that the combination of advanced data analytics, autonomous equipment, and integrated methodologies is transforming the landscape of subsurface engineering. Embracing innovative solutions like smart sensors and hybrid trenching strategies not only enhances safety but also ensures project resilience amid growing urban complexities. Engaging with authoritative standards and industry-driven research accelerates this evolution, positioning professionals to lead in innovation. We invite you to deepen your expertise by exploring these resources and sharing your insights—together, we shape the future of efficient, safe, and sustainable underground construction.