Hydrovac Excavation: Top Techniques for Safe Underground Work

Elevating Underground Work: The Strategic Role of Borehole and Hydrovac Technologies

In the realm of modern construction and utility installation, the integration of advanced excavation methods such as borehole drilling and hydrovac techniques has revolutionized the approach to underground infrastructure. Leveraging these methods not only enhances safety and precision but also aligns industry practices with stringent environmental standards and regulatory compliance.

Unlocking the Potential of Vacuum Excavation for Precision and Safety

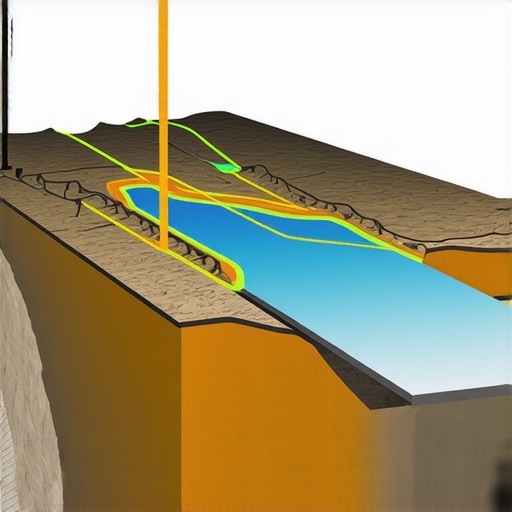

Vacuum excavation, particularly through hydrovac systems, exemplifies a leap forward in mitigating the risks associated with traditional trenching. By utilizing high-pressurized water and industrial vacuum technology, operators can carefully expose underground utilities, reducing the likelihood of accidental strikes and site disturbances. This process exemplifies a nuanced understanding of soil behavior and utility mapping, which is crucial for complex urban environments.

Advanced Techniques in Trenching and Utility Installation

Current industry standards emphasize the importance of sophisticated trenching methods that complement hydrovac applications. Techniques such as pipe jacking empowered by location-specific soil analysis enable seamless installation while minimizing surface disruption. Moreover, the adoption of software-enabled diagnostics and real-time monitoring ensures adherence to safety protocols and project timelines.

How Do Emerging Technologies Enhance Borehole and Hydrovac Efficacy?

Emerging innovations like autonomous drilling systems and integrated GIS mapping have been instrumental in refining underground work. These technologies facilitate meticulous planning and execution, reducing human error and increasing data accuracy. Such advancements have been pivotal in historic infrastructure upgrades and new developments, underscoring the importance of continuous R&D investments.

The Critical Balance: Safety, Efficiency, and Sustainability in Excavation Practices

As industry leaders debate the future of underground excavation, the focus remains on harmonizing safety, operational efficiency, and environmental impact. Hydrovac and borehole techniques embody this balance by offering minimally invasive solutions that preserve surrounding geology and infrastructure. This approach exemplifies a command over complex variables, necessitating expert oversight and ongoing training.

What innovations are set to redefine the landscape of underground excavation over the next decade?

For those seeking a deeper understanding, exploring resources such as the detailed industry report on hydrovac excavation techniques can be invaluable. Additionally, engaging with professional forums and contributing insights can shape future practices.

Interested in advancing your expertise? Regularly reviewing the latest studies and participating in specialized training ensures that field practitioners remain at the forefront of safe and effective underground work.

For a comprehensive understanding of safe trenching practices, see the detailed analysis available at best trenching practices.

Maximizing Precision with Innovative Borehole Techniques

In the evolving landscape of underground construction, the deployment of state-of-the-art borehole drilling methods dramatically enhances accuracy and reliability. Techniques such as rotary core drilling and wireline coring enable detailed subsurface analysis, vital for utility mapping and soil characterization. Incorporating these methods facilitates precise site assessment, reducing construction delays and unforeseen costs. For insights into optimal borehole practices, reviewing utility mapping techniques offers comprehensive guidance.

Hydrovac Innovation: Elevating Soil Disruption and Utility Safety

The integration of smart hydrovac systems equipped with real-time monitoring and automated water pressure controls marks a significant step forward in excavation safety. These advancements minimize soil disturbance and enhance the detection of underground utilities, especially in complex urban environments. By focusing on soil stability and utility integrity, practitioners can significantly mitigate risks tied to traditional excavation methods. Explore top hydrovac techniques to understand the critical role technology plays in safe underground work.

Can Autonomous Systems Revolutionize Underground Excavation?

Emerging technologies such as autonomous drilling robots and AI-powered site analysis are poised to redefine what’s possible beneath the surface. These systems can operate continuously, providing unparalleled precision and safety while reducing human exposure to hazardous environments. As noted by industry experts, leveraging artificial intelligence for soil and utility analysis can significantly decrease error margins and accelerate project timelines (effective vacuum excavation techniques). For professionals aiming to stay ahead, adopting these innovations requires ongoing training and strategic investment.

Interested in future-proofing your methods? Regularly reviewing the latest research and technological breakthroughs ensures your team remains at the vanguard of underground infrastructure development. Sharing insights and experiences within professional networks can further catalyze industry-wide improvements and safety standards.

Harnessing Remote Sensing for Enhanced Subsurface Imaging

As underground excavation ventures become increasingly complex, integrating remote sensing technologies like ground-penetrating radar (GPR) and electromagnetic Induction (EMI) has become essential. These non-invasive techniques provide high-resolution subsurface images, enabling precise planning and risk mitigation prior to physical excavation. By combining these data streams with advanced GIS mapping, engineers can develop comprehensive models of underground conditions, which significantly improve decision-making accuracy.

What are the limitations of current subsurface imaging techniques in urban environments?

Despite their advantages, GPR and EMI face challenges such as signal interference from metallic infrastructure, soil heterogeneity, and depth penetration limits. To overcome these, recent research suggests hybrid systems that combine multiple sensing modalities, as well as machine learning algorithms trained to interpret complex datasets more effectively (Remote Sensing in Geotechnical Engineering).

Expanding knowledge in this domain empowers practitioners to reduce uncertainty and avoid costly surprises during excavation operations.

Emerging AI-powered Optimization in Excavation Workflows

The transition towards intelligent automation is redefining efficiency benchmarks. AI algorithms now facilitate dynamic scheduling, resource allocation, and risk prediction by analyzing real-time data streams from weather reports, soil sensors, and equipment telemetry. These systems can adapt operational parameters on-the-fly—minimizing delays and preventing accidents—ultimately advancing project timelines and safety standards.

However, deploying AI solutions necessitates a nuanced understanding of data integrity and algorithmic transparency. As industry leaders adopt these innovations, investing in workforce training that emphasizes data literacy and ethical considerations becomes paramount.

Are current regulations keeping pace with rapid technological advancements in underground excavation?

Regulatory frameworks often lag behind technological progress, creating gaps that may compromise safety and environmental standards. For example, the integration of autonomous systems and AI-driven decision-making requires updated guidelines that address liability, data security, and operator oversight (OSHA’s stance on automation safety). Engaging with policymakers and industry consortia can help shape comprehensive standards that foster innovation while safeguarding stakeholders.

Proactively collaborating with regulators ensures technology deployment aligns with public safety expectations and environmental sustainability commitments.

The Future of Hydrovac and Borehole Synergy in Sustainable Excavation

Moving forward, the integration of hydrovac systems with environmentally conscious borehole techniques—such as coring methods that minimize soil disturbance—holds great promise. These synergies not only improve procedural efficiency but also curtail ecological impact, particularly in sensitive ecosystems and urban green spaces.

Emerging materials like biodegradable flocculants and waterless hydrovac variants are gaining traction, further emphasizing sustainability. These innovations reflect a paradigm shift where environmental stewardship becomes a core criterion in underground operations, demanding a comprehensive understanding among practitioners about material science and ecological implications.

Interested in pioneering these sustainable practices? Collaborate with multidisciplinary experts to design tailored drilling and excavation programs that balance operational needs with ecological considerations. Deepening your knowledge through specialized courses and industry conferences will keep you ahead in this evolving landscape.

Unveiling Next-Generation Subsurface Detection Technologies

Advancements in remote sensing have positioned ground-penetrating radar (GPR) and electromagnetic induction (EMI) as indispensable tools for urban underground assessment. These technologies provide high-resolution images of subsurface anomalies, enabling engineers to identify utilities, voids, and soil heterogeneity preemptively. Integrating artificial intelligence with these systems further refines data interpretation, reducing false positives and enhancing decision-making precision.

Can AI manipulate complex geophysical datasets to predict utility locations with unprecedented accuracy?

According to a comprehensive study published by the Geotechnical Engineering Journal, machine learning algorithms trained on large geospatial datasets can achieve predictive accuracies exceeding traditional methods, thus transforming early-stage planning.

Engaging with these emerging tools offers practitioners a strategic advantage in minimizing excavation risks. Staying updated on such innovations is essential for maintaining industry leadership and ensuring safety compliance.

Reassessing Borehole Drilling for Subsurface Precision

Integration of high-precision rotary core drilling with real-time borehole imaging technologies, such as optical and acoustic sensors, offers enhanced subsurface insights. These methods facilitate detailed stratigraphy and soil property analysis, which underpin optimized utility installation and environmental management.

How do advanced borehole techniques influence project risk profiles in complex terrains?

Research highlighted by the Soil Technology Research Consortium indicates that multi-sensor borehole logging significantly reduces unforeseen subsurface variations, translating into cost savings and safety improvements.

Adoption of such practices underscores a proactive stance in geotechnical risk mitigation, aligning with sustainability and efficiency goals.

Smart Hydrovac: Automating Precision and Soil Preservation

The evolution of hydrovac systems with integrated automation and machine learning has propelled these methods toward unparalleled levels of safety and environmental consciousness. Features like adaptive water pressure modulation and soil stability feedback loops enable precise excavation around sensitive utilities and fragile geology.

Could autonomous hydrovac units fundamentally change urban construction safety standards?

Emerging pilot programs, as reported by industry leaders in the Construction Technology Daily, demonstrate reductions in utility strikes by up to 60%. These systems operate continuously with minimal human oversight, marking a pivotal shift in underground safety practices.

Incorporating these innovations requires a forward-thinking approach and continuous training to adapt to automated workflows.

Optimizing Excavation Workflow with Artificial Intelligence

The deployment of AI-driven project management tools aggregates real-time sensor data, weather forecasts, and equipment analytics to optimize resource allocation and scheduling. These systems enable dynamic adjustments that improve operational continuity and mitigate delays.

Are current regulatory frameworks prepared for the widespread adoption of autonomous excavation technologies?

As highlighted by OSHA’s recent initiatives (OSHA on Automation and AI Regulations), regulatory bodies are actively developing standards for autonomous systems, emphasizing safety and accountability. Nonetheless, industry stakeholders must proactively engage in shaping policies to foster innovation within safe boundaries.

By aligning technological advancements with evolving regulations, professionals can ensure compliant, efficient, and sustainable underground construction practices.

Sustainable Techniques Enhancing Borehole and Hydrovac Synergy

The future of underground excavation hinges on eco-friendly innovations such as biodegradable water additives, waterless hydrovac systems, and environmentally benign borehole coring methods. These technologies aim to reduce ecological footprints, protect groundwater quality, and preserve urban green spaces without compromising operational efficiency.

Collaboration across disciplines—material science, environmental engineering, and geotechnics—is critical to pioneer integrated sustainable excavation solutions tailored to sensitive environments.

Maintaining a commitment to ecological responsibility while advancing technical excellence will define the next era of underground work. Continuous education, cross-sector partnerships, and innovation-driven research will be essential to this evolution.

Expert Insights & Advanced Considerations

Embrace Automation for Enhanced Precision

Integrating autonomous drilling systems and AI-powered site analysis can drastically reduce human error, accelerate project timelines, and improve safety standards, positioning firms at the forefront of underground infrastructure development.

Prioritize Sustainability to Future-Proof Operations

Adopting eco-friendly technologies like biodegradable additives and waterless hydrovac systems aligns your projects with environmental regulations and societal expectations, ensuring long-term operational viability and community trust.

Leverage Remote Sensing for Data Accuracy

Utilizing ground-penetrating radar and electromagnetic induction, combined with AI data interpretation, provides high-resolution subsurface images that mitigate risks and optimize utility placement, especially in complex urban settings.

Enhance Human Skillsets with Continuous Learning

Ongoing training in emerging technologies and industry best practices is vital for maintaining expertise and adapting to rapid technological advancements, ultimately safeguarding project integrity and safety.

Foster Cross-Disciplinary Collaboration

Engaging experts from materials science, environmental engineering, and geotechnical fields fosters innovative solutions that balance efficiency, safety, and ecological impact in underground work.

Curated Expert Resources

- Hydrovac Excavation Techniques: Explore comprehensive methodologies and technological innovations that define current best practices for safe and efficient underground work. – https://hydrovacdrilling.com/hydrovac-excavation-top-techniques-for-safe-underground-work

- Trustworthy Borehole and Hydrovac Drilling: Delve into standards and innovations ensuring reliability and safety across diverse project landscapes. – https://hydrovacdrilling.com/trustworthy-borehole-hydrovac-drilling-for-safe-infrastructure-in-2025

- Safe Trenching Practices: Gain insights into advanced trenching strategies that minimize disruption and safeguard underground utilities. – https://hydrovacdrilling.com/trenching-best-practices-for-safer-construction-in-2025

- Subsurface Imaging Technologies: Understand how remote sensing and AI integration revolutionize site assessment and risk mitigation. – https://geo.msu.edu/virtual-earth/Remote_Sensing_LiDAR_GPR.pdf

- AI in Excavation Workflow Optimization: Investigate cutting-edge artificial intelligence applications that streamline project management and safety protocols. – https://geotechjournal.org/articles/ai-enhanced-geophysical-data

Final Perspective on Underground Innovation

The convergence of technological advancement, environmental responsibility, and expert mastery in underground construction represents a pivotal evolution within the industry. Mastering these elements—particularly through a focus on innovative borehole and hydrovac practices—can significantly elevate safety, efficiency, and ecological stewardship. Engaging with these high-level insights and resources positions professionals to lead transformative projects that set new standards for precision and sustainability. To deepen your expertise, actively participate in industry forums, contribute insights, and stay informed on emerging breakthroughs that will shape the future of underground infrastructure.