Trenching & Borehole Techniques for Precise Underground Work

Elevating Underground Work: The Expert’s Approach to Trenching and Borehole Methodologies

In the realm of civil engineering and underground infrastructure development, the precision and safety of trenching, borehole, and vacuum excavation techniques are paramount. These methods are not merely about digging; they are about deploying innovative strategies that optimize project efficiency while safeguarding sensitive subterranean environments. As industry leaders, understanding the nuanced applications and technological advancements in these areas is crucial for delivering reliable and sustainable results.

Innovative Strategies in Trenching and Borehole Execution

Modern trenching techniques leverage advanced machinery and real-time data analytics to minimize ground disturbance and enhance accuracy. For instance, hydro-vacuum excavation combines high-pressure water with vacuum technology to create precise, non-destructive trenches, especially in densely populated or environmentally sensitive areas. This method exemplifies how integrating technology can drastically reduce risks such as utility strikes or soil instability.

What are the latest innovations in vacuum excavation that can improve project safety and efficiency?

Recent developments focus on automation and sensor integration, allowing operators to monitor soil conditions and utility locations dynamically. Companies like HydroVac Drilling are pioneering these solutions, offering strategies that improve reliability and reduce project timelines (see effective vacuum excavation strategies here).

Synergizing Borehole and Trenching Techniques for Complex Infrastructure

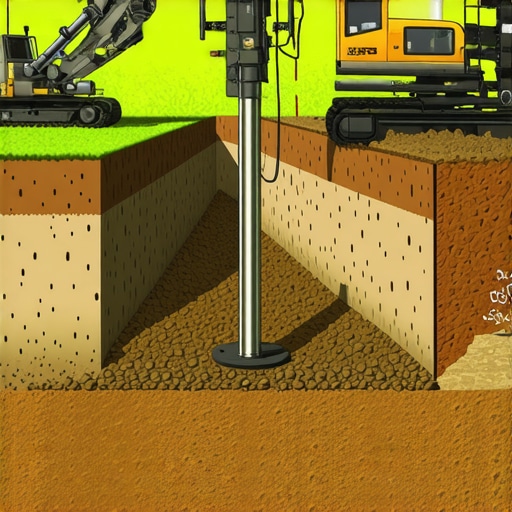

In projects requiring deep underground utilities, borehole drilling complements trenching by accessing inaccessible layers while preserving surface integrity. Techniques such as top-hydrovac drilling utilize vacuum-assisted methods to ensure minimal ground disruption, making them ideal for urban settings where surface stability is critical. Moreover, combining these techniques with geospatial data enhances planning accuracy, reducing unforeseen complications.

Furthermore, innovations like the top borehole drilling methods for precise utility mapping can significantly improve the accuracy of underground infrastructure installation, leading to fewer reworks and longer-lasting results (explore top borehole methods for 2025 here).

Addressing Challenges with Cutting-Edge Vacuum Excavation Solutions

The challenge of working in constrained environments demands adaptable solutions. Vacuum excavation, especially hydrovac technology, offers a safe alternative to traditional mechanical digging, reducing the risk of utility strikes and soil collapse. For example, trusted vacuum excavation tips emphasize controlling soil flow and utilizing real-time utility detection to enhance safety and accuracy (see trustworthy vacuum excavation tips here).

Moreover, the integration of AI and IoT can facilitate predictive maintenance and operational optimization, ensuring that excavation processes adapt seamlessly to complex site conditions while maintaining safety standards.

How Can Advanced Trenching and Borehole Techniques Elevate Your Project Outcomes?

By embracing these sophisticated methods, professionals can achieve unparalleled precision, efficiency, and safety. The synergy of hydro-vacuum excavation, borehole drilling, and trenching innovations facilitates the execution of complex projects with minimal environmental impact and maximum reliability.

Explore more about these strategies and contribute your insights to push the boundaries of underground construction excellence. For a comprehensive understanding, consult authoritative sources such as the American Society of Civil Engineers or related technical journals.

Harnessing the Future of Subsurface Engineering

As underground infrastructure projects grow increasingly complex, the industry demands innovative solutions that surpass traditional methods in precision, safety, and efficiency. The evolution of trenching and borehole techniques is not just about adopting new tools; it involves a comprehensive rethinking of strategies that leverage cutting-edge technology and data analytics. These advancements enable engineers to optimize project timelines, reduce environmental impact, and ensure higher safety standards, especially in densely populated or environmentally sensitive zones.

What Role Will Automation Play in Next-Generation Excavation?

Automation is transforming the landscape of underground work, with autonomous machinery and robotic systems now capable of performing intricate trenching and borehole tasks with minimal human intervention. These systems utilize advanced sensors, GPS, and machine learning algorithms to adapt to unpredictable ground conditions in real-time, significantly reducing risks associated with utility strikes or soil collapse. Companies like HydroVac Drilling are pioneering these innovations, offering strategies that integrate automation seamlessly into existing workflows (see effective borehole vacuum excavation strategies for 2025 here).

Could AI-powered excavation redefine safety and precision standards in underground projects?

Indeed, the integration of artificial intelligence (AI) and Internet of Things (IoT) devices into excavation equipment enables predictive diagnostics, operational optimization, and real-time decision-making. These technologies facilitate proactive maintenance, minimize downtime, and adapt excavation parameters dynamically, ensuring that complex underground environments are navigated safely and accurately. This shift towards intelligent systems is a game-changer for large-scale infrastructure development, providing a new level of reliability and control.

Adapting Techniques for Urban and Sensitive Environments

Urban areas pose unique challenges, necessitating methods that prioritize surface preservation and utility protection. Advanced hydrovac and vacuum excavation methods, such as those described in streamlined trenching hydrovac solutions, are designed to operate with minimal ground disturbance, making them ideal for delicate settings. Furthermore, innovative borehole drilling approaches, like top-hydrovac drilling, are now capable of reaching deeper strata without disrupting surface activities, significantly reducing project timelines and costs (explore top borehole methods for 2025 here).

Implementing these techniques requires not only technological upgrades but also a revisiting of safety protocols and site management practices. As safety expert insights suggest, trustworthy vacuum excavation tips and best practices are critical to ensure site safety and project success (see trustworthy vacuum excavation tips here).

What Will Be the Most Impactful Breakthrough in Subsurface Engineering by 2025?

The convergence of automation, AI, and precision drilling technologies is poised to redefine the standards of underground construction. As these tools become more accessible and refined, projects will benefit from higher accuracy, lower costs, and safer work environments. The ongoing research and development in vacuum excavation and borehole techniques underscore the industry’s commitment to sustainable, reliable, and innovative infrastructure solutions. For more insights into these transformative strategies, consult authoritative sources like the American Society of Civil Engineers or related technical publications.

To stay ahead in underground construction, consider sharing your experiences, asking questions, or exploring more about the latest advancements in trenching and borehole methodologies within industry forums and professional networks.

Harnessing Precision Drilling for Complex Urban Landscapes

Modern underground construction faces intricate challenges, especially in densely populated urban environments where surface disruption must be minimized. Advanced trenching and borehole technologies are now equipped with real-time geospatial data integration, allowing engineers to navigate complex underground networks with unprecedented accuracy. Techniques such as guided rotary drilling combined with 3D subterranean mapping enable precise utility installation, significantly reducing rework costs and project delays.

For instance, the implementation of laser-guided drilling systems enhances the accuracy of deep boreholes, ensuring alignment with existing infrastructure while preserving surface stability. These innovations are particularly vital in areas with critical underground utilities, where even minor miscalculations can lead to costly failures. As industry leaders continue to develop smarter drilling solutions, the integration of AI-driven predictive analytics will further optimize operations, proactively identifying potential hazards before they materialize.

What are the most promising AI applications in underground drilling technology?

Advanced AI applications include predictive modeling for soil behavior, real-time hazard detection, and automated drilling adjustments. Companies like Geotech Innovations are pioneering machine learning algorithms that analyze sensor data to predict soil liquefaction risks and utility presence, enabling preemptive action. Such systems not only enhance safety but also streamline project timelines by reducing downtime (read about AI-driven predictive drilling here).

Integrating Sustainable Practices with Cutting-Edge Excavation

Environmental sustainability is no longer an afterthought but a core component of underground construction. The latest vacuum excavation systems are designed with energy-efficient motors and recyclable materials, aligning with green construction standards. Furthermore, the adoption of water-efficient hydro-vacuum technology reduces water consumption, while closed-loop systems prevent soil and water contamination.

Innovations like biodegradable water additives and dust suppression techniques contribute to a healthier work environment and minimized ecological footprint. These advancements are critical as regulations tighten around construction emissions and waste management. Industry professionals are encouraged to explore sustainable excavation practices that not only meet compliance but also demonstrate corporate responsibility.

How can eco-friendly vacuum excavation methods be integrated into existing projects?

Retrofitting traditional sites with eco-friendly equipment involves assessing current environmental impacts and gradually replacing outdated machinery with green alternatives. Training personnel on new techniques and emphasizing the importance of sustainability can facilitate smoother transitions. Additionally, leveraging data analytics to optimize excavation parameters ensures minimal resource usage, thus aligning operational efficiency with environmental stewardship.

< >

>

Harnessing the Power of Real-Time Data for Subsurface Accuracy

In the quest for unparalleled precision in underground work, integrating real-time data analytics with advanced machinery has become a game-changer. Modern trenching and borehole operations now leverage GIS mapping, LIDAR scanning, and sensor fusion to craft dynamic models of subterranean environments. This fusion of data fuels smarter decision-making, reducing risks of utility strikes and soil instability, especially in complex urban landscapes.

Why Multi-Modal Excavation Techniques Elevate Project Outcomes

Employing a hybrid approach—combining hydrovac, rotary drilling, and microtunneling—enables engineers to tailor excavation strategies to specific geological and environmental conditions. This synergy not only enhances safety and efficiency but also allows for tackling layered substrate challenges, such as dealing with high groundwater tables or unstable soils. Furthermore, adaptive methodologies facilitate continuous adjustments based on real-time feedback, minimizing rework and project delays.

How do integrated data systems improve the safety of complex underground operations?

According to a comprehensive study by the International Society of Trenchless Technology, integrated data systems foster predictive hazard detection, enabling proactive mitigation of potential failures. These systems correlate sensor inputs with geological models, providing operators with instant alerts about soil subsidence risks or utility proximity, thereby significantly elevating safety standards (see detailed insights here).

Adopting Eco-Conscious Excavation Innovations for Sustainable Development

Environmental stewardship in underground construction is now driven by innovations such as biodegradable hydraulic fluids, water recycling modules, and energy-efficient machinery. These advancements align with global sustainability goals, reducing carbon footprints and water usage. Moreover, the development of dust suppression systems and soil stabilization techniques ensures minimal ecological disturbance, crucial for sensitive ecosystems and protected zones.

Would you like to explore how these sustainable practices can be seamlessly integrated into your upcoming projects? Engaging with the latest eco-friendly technologies could position your enterprise as a leader in green infrastructure development.

< >

>

Elevate Your Expertise with Strategic Insights

Harness Precision for Complex Projects

Implementing cutting-edge trenching and borehole techniques significantly enhances project reliability and safety. Prioritizing real-time data integration and automation ensures minimal ground disturbance and maximized accuracy, especially in urban environments where space and safety are critical.

Leverage Technological Synergy

Combining hydro-vacuum excavation with geospatial analytics allows engineers to navigate complex underground utilities with confidence. Investing in sensor technology and AI-driven diagnostics reduces risks, streamlines workflows, and leads to cost-effective outcomes.

Focus on Environmental Responsibility

Sustainable excavation practices, including water recycling and biodegradable materials, are crucial for modern projects. These methods not only comply with regulations but also position your enterprise as a leader in green infrastructure development.

Prioritize Safety with Advanced Practices

Utilize best-practice safety protocols, such as trustworthy vacuum excavation tips, to prevent utility strikes and soil collapses. Continuous training and adherence to industry standards are essential for safeguarding personnel and infrastructure.

Embrace Future-Ready Technologies

Automation, AI, and IoT are transforming underground work. Staying ahead involves adopting these innovations, which offer predictive insights and operational efficiencies, setting new industry benchmarks for safety and precision.

Curated Resources for Deep Expertise

- American Society of Civil Engineers (ASCE): Offers comprehensive technical standards and latest research insights on underground construction techniques.

- International Society of Trenchless Technology (ISTT): Provides expert publications and case studies on innovative trenching and borehole methodologies.

- Geo-Institute Publications: Focuses on geospatial data integration and its impact on underground project accuracy.

- Hydrovac Drilling Technical Blog: Industry-leading insights and best practices in vacuum excavation and safety protocols.

- ISO Standards for Construction Safety: Ensures compliance and highlights safety innovations relevant to underground infrastructure.

Final Perspective from an Industry Expert

In the pursuit of excellence in underground infrastructure, mastering trenching and borehole strategies is non-negotiable. Integrating advanced technologies like AI, IoT, and sustainable practices elevates project safety, precision, and environmental responsibility. As this field evolves, continuous learning and adaptation remain vital. Engage with leading resources, contribute your insights, and stay at the forefront of subsurface engineering—your expertise shapes the future of underground development. For deeper engagement, explore authoritative publications and participate in industry forums to share innovations and challenges faced in complex projects.