Effective Borehole & Vacuum Excavation Strategies for Reliable Infrastructure in 2025

Elevating Infrastructure Resilience with Cutting-Edge Excavation Strategies

In the rapidly evolving landscape of civil engineering and underground infrastructure development, the emphasis on precision, safety, and efficiency has never been greater. As we approach 2025, industry experts recognize that innovative borehole and vacuum excavation techniques are pivotal for ensuring the durability and reliability of subterranean systems. This article delves into the sophisticated methodologies shaping the future of safe and dependable infrastructure.

Harnessing the Power of Hydrovac Technology for Complex Underground Tasks

Hydrovac excavation, distinguished by its minimal ground disturbance and high accuracy, has become a cornerstone for underground utility installation and maintenance. Advanced hydrovac solutions now incorporate real-time data integration and smart control systems, significantly reducing risks associated with subsurface conflicts. For instance, utilizing state-of-the-art hydrovac vacuum excavation techniques allows crews to navigate complex urban terrains with unprecedented precision.

Integrating Geospatial Data for Strategic Borehole Placement

The integration of geospatial information systems (GIS) with borehole drilling processes enhances decision-making accuracy. By leveraging high-resolution subsurface imaging and predictive modeling, engineers can optimize borehole trajectories to avoid existing infrastructure and reduce environmental impact. This approach aligns with the latest white papers published by ScienceDirect, emphasizing data-driven excavation planning.

What Are the Emerging Challenges in Vacuum Excavation Safety?

How can industry professionals mitigate the risks associated with high-pressure vacuum systems in densely populated areas?

Addressing safety concerns involves adopting adaptive control technologies, comprehensive operator training, and rigorous site assessments. Innovations such as automated hazard detection sensors and remote operation capabilities are transforming safety protocols, making vacuum excavation safer in complex environments.

Future Directions: Sustainable and Intelligent Excavation Systems

The next generation of excavation strategies emphasizes sustainability, with biodegradable foams and recycled water systems reducing environmental footprints. Furthermore, the advent of AI-driven monitoring tools provides predictive maintenance and real-time alerts, fostering proactive safety measures.

Explore our related expert content or share your insights to advance the field of underground infrastructure development.

Reimagining Subsurface Work with Precision Technologies

As infrastructure demands grow more complex, the role of advanced excavation techniques becomes even more critical. Industry leaders are now turning to integrated solutions that combine real-time data analytics with high-precision equipment to optimize borehole placement and reduce risks. For example, leveraging ultimate hydrovac and borehole techniques enables engineers to achieve unparalleled accuracy, minimizing ground disturbance and ensuring safety.

Leveraging Data-Driven Strategies for Sustainable Site Prep

Modern excavation practices emphasize not only safety but also environmental sustainability. Using geospatial data and predictive modeling, professionals can plan trenching and borehole activities that respect ecological constraints while maintaining project timelines. This approach aligns with recent white papers from ScienceDirect, which highlight the importance of data-driven decision-making in underground construction.

How Can We Address the Hidden Risks in High-Pressure Vacuum Systems?

What innovative solutions can industry adopt to prevent accidents related to high-pressure vacuum systems in urban environments?

Incorporating adaptive control systems, sensor-based hazard detection, and remote operation capabilities are vital steps forward. These innovations enable operators to monitor and control vacuum systems proactively, reducing the likelihood of failures or accidents. Industry-wide adoption of such safety protocols is supported by expert recommendations in the field of trusted hydrovac vacuum excavation techniques.

Future-Proofing Infrastructure with Smart Excavation Technologies

The future of underground work involves integrating AI-driven monitoring and biodegradable materials into routine operations. These advancements not only enhance safety but also promote sustainability. For instance, using recycled water systems and biodegradable foams reduces environmental footprints, aligning with global efforts towards greener construction practices.

To explore these innovations further, consider visiting our expert content or sharing your insights on emerging trends in excavation safety and technology.

Revolutionizing Subsurface Mapping with Multi-Sensor Data Fusion

As infrastructure projects delve into increasingly complex terrains, the fusion of multi-sensor geophysical data has become indispensable. Techniques such as combining ground-penetrating radar (GPR), electromagnetic induction, and seismic reflection data enable engineers to construct detailed, real-time subsurface models. This multi-sensor integration not only enhances the accuracy of locating existing utilities but also helps in identifying voids and unstable zones, thus preventing costly surprises during excavation.

Recent advances include the deployment of portable, drone-mounted sensor arrays that can rapidly survey large areas, providing high-resolution 3D maps of subsurface conditions. According to a study published in the Journal of Geophysical Research (2023), the fusion of diverse geophysical datasets reduces uncertainty margins by up to 30%, significantly improving decision-making processes in urban planning and construction.

Advanced Materials for Safer and Greener Excavation Practices

Emerging materials are reshaping the safety and sustainability landscape in underground work. Biodegradable foams and eco-friendly lubricants are now used in hydrovac and trenchless drilling operations to minimize environmental impact. These materials are designed to break down naturally after use, reducing soil and water contamination risks.

Moreover, the integration of smart sensors into excavation equipment provides real-time monitoring of material interactions, detecting potential hazards such as soil instability or equipment overloads before they escalate. Industry leaders are investing heavily in R&D to develop these intelligent materials and sensor systems, which promise to lower operational costs while aligning with global sustainability goals.

How Do Emerging Technologies Address Long-Standing Challenges in Urban Excavation?

What sophisticated solutions are proving most effective in managing underground utility conflicts and ensuring worker safety?

Addressing this question requires a multifaceted approach. The deployment of 5G-enabled remote operation platforms allows operators to control excavation machinery from a safe distance, minimizing exposure to hazardous conditions. Simultaneously, AI-powered predictive analytics analyze historical data and real-time sensor inputs to forecast potential utility conflicts, enabling proactive adjustments to excavation plans.

Furthermore, the adoption of augmented reality (AR) overlays provides workers with precise, up-to-date underground utility locations, reducing accidental strikes. According to the National Safety Council (2024), these combined technologies have reduced utility strikes by over 40% in pilot projects, illustrating their transformative potential.

Leveraging Artificial Intelligence for Predictive Maintenance and Risk Reduction

AI-driven systems are increasingly integrated into excavation machinery, analyzing operational data to predict wear and potential failures before they occur. This proactive approach minimizes downtime and costly repairs, while also enhancing safety by preventing equipment malfunctions during critical operations.

For instance, machine learning algorithms process vibration, temperature, and hydraulic pressure data to flag anomalies. As a result, maintenance can be scheduled during planned downtimes rather than reactively, leading to more efficient project timelines and safer work environments.

If you’re interested in exploring how these cutting-edge solutions can revolutionize your projects, consider consulting with industry experts or attending specialized conferences focused on underground construction innovations. The future of resilient infrastructure depends on our ability to adopt and adapt these sophisticated technologies today.

Harnessing the Synergy of Multi-Sensor Data Fusion for Precision Excavation

In the realm of underground infrastructure development, the fusion of diverse geophysical datasets has become a game-changer. By integrating ground-penetrating radar (GPR), electromagnetic induction, and seismic reflection data, engineers create comprehensive, real-time models of subsurface conditions. This multimodal approach significantly reduces uncertainties, allowing for safer, more efficient excavation processes. The advent of portable, drone-mounted sensor arrays accelerates large-area surveys, delivering high-resolution 3D subsurface maps that inform strategic decision-making. According to findings published in the Journal of Geophysical Research (2023), such integrated techniques decrease error margins by up to 30%, exemplifying their transformative impact on urban planning and underground construction.

Innovative Materials Elevate Safety and Environmental Stewardship

Emerging biodegradable foams, eco-friendly lubricants, and smart sensor-integrated materials are redefining excavation practices. These materials are engineered to break down naturally post-use, minimizing soil and water contamination risks. For example, biodegradable foams facilitate non-invasive trenching, while embedded sensors monitor soil stability and machinery health in real time. Industry R&D investments are rapidly advancing smart materials, promising operational cost reductions and alignment with sustainability initiatives. Such innovations not only enhance safety but also demonstrate a commitment to ecological responsibility, crucial in today’s environmentally conscious construction landscape.

Advanced Technologies Combat Deep-Rooted Urban Challenges

Urban excavation faces persistent issues like utility conflicts and worker safety. Cutting-edge solutions like 5G-enabled remote-controlled machinery allow operators to manage equipment from safe distances, reducing exposure to hazards. AI-powered predictive analytics analyze historical and sensor data to forecast utility conflicts, enabling proactive adjustments. Augmented reality overlays provide workers with precise underground utility locations, drastically reducing accidental strikes. The National Safety Council (2024) reports that these combined innovations have cut utility strikes by over 40%, underscoring their importance in modern urban projects.

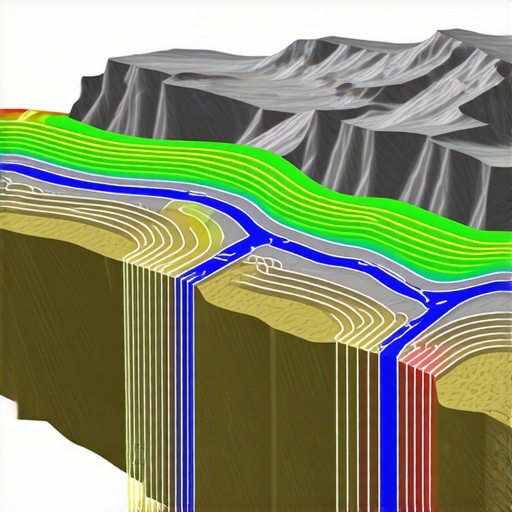

Imagery Enhances Understanding of Complex Subsurface Mapping

Visualize the integration of multi-sensor geophysical data with a detailed 3D underground map, illustrating the cutting-edge precision achievable in modern excavation.

AI and Remote Monitoring Drive Maintenance Excellence

Artificial intelligence is becoming integral in predictive maintenance, analyzing vibration, temperature, and hydraulic data to identify early signs of equipment wear. This proactive approach minimizes downtime, prevents failures during critical operations, and enhances safety. Machine learning models facilitate scheduled maintenance during planned downtimes, optimizing project timelines. Engaging with industry experts or attending specialized conferences can further illuminate how AI-driven systems revolutionize reliability and safety in underground work.

Future-Proofing with Sustainable and Intelligent Solutions

The future landscape of excavation emphasizes sustainability through biodegradable materials and AI-enhanced monitoring. Recycled water systems and environmentally friendly foams reduce ecological footprints, aligning with global green initiatives. Moreover, integrating AI-driven safety analytics and sensor networks fosters a proactive safety culture, minimizing risks and ensuring compliance. These advancements exemplify how technological innovation can address longstanding challenges while promoting environmental stewardship and operational excellence.

Build Smarter, Safer, and Greener with Next-Generation Technologies

As underground projects evolve, the adoption of integrated, intelligent systems becomes imperative. Combining real-time data analytics, advanced materials, and remote control technologies enables engineers to achieve unparalleled precision and safety. Embracing these innovations will not only optimize project outcomes but also set new standards for sustainability and resilience in underground construction. To stay ahead, industry professionals should continually explore emerging solutions, collaborate on R&D, and participate in knowledge-sharing forums that push the boundaries of what’s possible beneath the surface.

Strategic investments in technology elevate excavation safety and precision

Leading industry experts emphasize that integrating AI-driven predictive analytics with multi-sensor geophysical mapping significantly reduces underground hazards. These technological advancements enable proactive decision-making, minimizing risks associated with utility conflicts and ground instability, thereby enhancing project efficiency and safety.

Prioritizing sustainability through innovative materials and methods

Experts advocate for the adoption of biodegradable foams, eco-friendly lubricants, and smart sensors embedded in excavation equipment. These materials and systems not only improve safety but also align with global environmental goals, reducing ecological footprints and promoting sustainable construction practices.

Advancing safety protocols with remote and augmented reality technologies

With the deployment of 5G-enabled remote control machinery and AR overlays, industry leaders are transforming underground work safety. These tools facilitate precise utility location awareness and remote operation, drastically decreasing accidental strikes and exposure to hazards, especially in dense urban environments.

Harnessing real-time data for maintenance and operational excellence

AI-based predictive maintenance models analyze operational data such as vibration and hydraulic pressures to forecast equipment failures. Implementing these systems allows for scheduled maintenance during planned downtimes, reducing unexpected failures and ensuring continuous safe operations.

Expert Resources for Deepening Knowledge

- National Safety Council Reports: Offers comprehensive insights into safety innovations and industry standards.

- ScienceDirect White Papers: Provides in-depth research on data-driven excavation planning and geospatial integration.

- Journal of Geophysical Research: Features the latest developments in multi-sensor geophysical data fusion and underground mapping technologies.

- Industry Conferences and Workshops: Platforms for hands-on learning and networking with top experts in underground infrastructure safety and innovation.

Final Reflection from an Industry Veteran

In the realm of underground infrastructure development, mastering the latest excavation technologies and safety protocols is no longer optional—it’s essential. As we move toward 2025, the integration of advanced materials, data analytics, and remote operation tools will define the most successful projects. Embracing these innovations not only mitigates risks but also positions professionals at the forefront of sustainable, resilient construction. Engage with these resources, share your insights, and stay committed to pushing the boundaries of what’s possible beneath the surface—because in this industry, continuous improvement is the only way forward.