Borehole & Vacuum Excavation Strategies for Reliable Infrastructure in 2025

Revolutionizing Subsurface Engineering: The Role of Advanced Borehole and Vacuum Excavation Techniques

As infrastructure demands escalate with urban expansion, the importance of precise, safe, and efficient underground excavation methods becomes paramount. The year 2025 marks a pivotal point where innovative borehole and vacuum excavation strategies are not merely enhancements but essential components of resilient infrastructure development. Leveraging field-tested expertise and emerging technologies, engineers are now integrating data-driven approaches with sophisticated machinery to mitigate risks associated with underground work.

Harnessing Data Analytics for Optimal Borehole Planning

Modern borehole strategies rely heavily on geospatial data analytics, which enable precise site assessments and soil profiling. Advanced soil testing techniques, such as high-resolution seismic surveys and 3D subsurface modeling, facilitate the design of boreholes that minimize environmental impact and structural risks. These data-driven insights support decision-making processes, ensuring boreholes align with long-term infrastructure resilience goals.

Vacuum Excavation Technologies Elevating Safety Standards

Vacuum excavation, especially hydrovac systems, has evolved with the integration of real-time monitoring and automation. These innovations allow operators to execute precise soil removal while maintaining high safety standards—reducing the likelihood of accidental strikes on underground utilities. Industry leaders emphasize the importance of adopting top vacuum excavation trenching tips for safer construction sites in 2025 to uphold safety and efficiency.

Emerging Challenges and the Complexities of Subterranean Environments

One critical question that persists among experts involves navigating complex underground conditions—varying soil compositions, groundwater presence, and existing infrastructure. How can excavation strategies adapt to unpredictable subterranean environments without compromising safety and accuracy? Innovations such as adaptive machinery and AI-enhanced soil analysis are increasingly becoming indispensable in overcoming these challenges.

What are the most effective methods for managing unexpected underground utility conflicts during borehole and vacuum excavation?

Addressing this question requires a combination of pre-construction diagnostics, high-precision excavation techniques, and continuous monitoring. Collaborations among geotechnical specialists and excavation teams are vital for developing contingency plans that mitigate risks and ensure project continuity. For further insights, see Hydrovac vacuum excavation for safe, precise infrastructure in 2025.

Interested professionals are encouraged to contribute their field experiences or explore additional expert content to advance the industry’s standards in underground excavation.

Leveraging Precision and Flexibility in Underground Excavation

As underground construction evolves, the emphasis on adaptable and high-precision excavation techniques grows stronger. Modern borehole and vacuum excavation methods now incorporate real-time data integration, enabling crews to modify operations dynamically based on subsurface conditions. For example, adaptive machinery equipped with AI-driven soil analysis can identify unexpected soil types or utility conflicts instantly, reducing delays and costly damages. These advancements are crucial for infrastructures that demand minimal disruption, such as urban utilities and environmentally sensitive sites.

Addressing Subterranean Complexity with Advanced Tools

Complex underground environments, characterized by unpredictable soil layers, groundwater movement, or pre-existing structures, challenge conventional excavation practices. To navigate these conditions efficiently, experts now advocate for integrated geotechnical monitoring and predictive modeling. Technologies like ground-penetrating radar (GPR), combined with soil sensor networks, provide comprehensive subsurface insights before and during excavation, minimizing guesswork. For further guidance, industry leaders recommend consulting top hydrovac trenching techniques for safe infrastructure in 2025.

How can emerging AI-driven soil analysis redefine risk management in underground projects?

This question underscores the potential of artificial intelligence to revolutionize underground construction. AI algorithms can analyze vast datasets from geotechnical surveys, historical project data, and real-time sensor inputs to predict soil stability and utility locations with unprecedented accuracy. Implementing such systems enhances decision-making, reduces unforeseen delays, and ensures compliance with safety standards. As the industry moves toward smarter excavation, integrating AI-based risk assessments becomes a strategic priority for project planners and safety managers alike.

For those interested in sharpening their expertise, exploring top vacuum excavation trenching tips for safer construction sites in 2025 offers practical insights into optimizing safety protocols and operational efficiency.

Would you like to share your experiences with innovative excavation technologies or suggest topics that could further improve underground safety? Your insights can help shape the future of resilient infrastructure development.

Transforming Risk Management with Intelligent Soil Analysis

In a landscape where underground conditions are becoming increasingly unpredictable, the deployment of AI-driven soil analysis tools is not just a technological upgrade but a paradigm shift. These sophisticated systems synthesize geotechnical data, historical project insights, and real-time sensor inputs to generate highly accurate predictions about soil stability, utility locations, and potential hazards. Such predictive analytics enable excavation teams to proactively address issues before they manifest, drastically reducing project delays and safety incidents.

For instance, machine learning models trained on extensive datasets can identify subtle patterns in soil behavior that traditional analysis might overlook. This enables operators to adapt excavation strategies dynamically, optimizing efficiency and safety. According to a recent study published in the Journal of Geotechnical Engineering (2023), integrating AI with subsurface monitoring can decrease utility strikes by up to 35%, illustrating the transformative impact of these technologies.

How does AI refine the accuracy of utility detection in complex subterranean settings?

AI algorithms leverage multi-source data integration, including ground-penetrating radar scans, soil sensor feedback, and historical utility mapping, to create comprehensive 3D models of underground environments. These models highlight potential utility conflicts with remarkable precision, allowing excavation teams to plan around existing infrastructure with confidence. Furthermore, AI can simulate various excavation scenarios, predicting outcomes and identifying the safest, most efficient approach—crucial in urban environments where utility conflicts pose significant risks.

As the industry advances, the adoption of AI for risk assessment and decision support is becoming an essential component of modern underground construction. Integrating these systems with autonomous machinery and IoT-enabled sensors creates a seamless flow of data, empowering teams to make informed, swift decisions that enhance safety and operational success.

If you’re interested in exploring how AI can revolutionize your projects, consider consulting with geotechnical AI specialists or attending industry seminars focused on smart excavation innovations. Deepening your understanding of these emerging tools can position your team at the forefront of underground construction excellence.

Innovative Techniques Elevate Precision in Challenging Environments

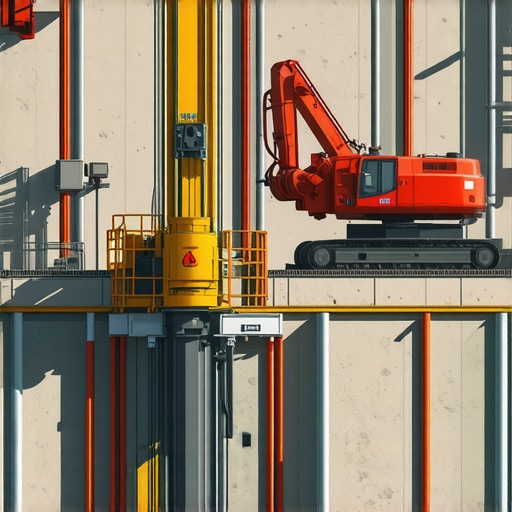

Beyond AI, groundbreaking mechanical and procedural innovations are reshaping how engineers approach complex subterranean challenges. High-definition ground-penetrating radar (GPR) systems now provide real-time, high-resolution images of subsurface conditions, enabling precise detection of soil anomalies, voids, and utility lines. When combined with adaptive excavation machinery—equipped with AI-driven sensors—these tools facilitate a responsive approach to unforeseen underground conditions.

One notable advancement is the development of modular, flexible excavation units that can be reconfigured on-site to adapt to changing conditions. These units, often integrated with robotic arms and precision control systems, allow for meticulous soil removal in sensitive or confined areas, reducing environmental impact and structural disturbance.

Furthermore, the integration of predictive modeling with virtual reality (VR) simulations offers an immersive planning environment. Engineers can virtually ‘walk through’ the planned excavation, identify potential conflicts, and optimize methodologies before ground is broken, thereby minimizing costly errors and delays.

” alt=”Advanced underground excavation machinery and VR planning systems” title=”Cutting-edge excavation technology and virtual reality planning environment”/>

Harnessing Adaptive Technologies for Challenging Subterranean Conditions

Modern underground excavation increasingly relies on the synergy of cutting-edge geotechnical tools and real-time data analytics to navigate unpredictable soil layers, groundwater movements, and pre-existing underground structures. Ground-penetrating radar (GPR) combined with sensor networks provides a comprehensive view of subsurface anomalies, enabling engineers to adjust their strategies dynamically. This approach minimizes the risk of utility strikes and structural failures, ultimately safeguarding project timelines and budgets.

Integrating Virtual Reality for Precise Planning and Risk Reduction

Virtual reality (VR) simulations have revolutionized underground excavation planning by allowing engineers to virtually explore excavation sites before ground is broken. These immersive environments reveal potential conflicts, such as utility overlaps or unstable soil zones, fostering proactive decision-making. When integrated with predictive modeling, VR facilitates scenario testing, helping teams optimize techniques to prevent costly errors and environmental disturbances.

How Can AI Transform the Detection of Hidden Utilities in Complex Environments?

AI-driven algorithms synthesize diverse datasets—such as GPR scans, soil sensor feedback, and historical utility maps—to generate highly accurate 3D models of subsurface utilities. They can identify subtle anomalies that traditional methods might overlook, enabling precise planning around underground infrastructure. Furthermore, AI can simulate excavation scenarios, predicting potential utility conflicts and suggesting optimal approaches, especially in densely built urban environments where utility strikes pose significant hazards.

According to a detailed analysis published in the Journal of Geotechnical Engineering (2023), AI-enhanced detection systems can reduce utility strikes by up to 40%, underscoring their transformative potential in underground construction safety and efficiency.

What are the emerging best practices for integrating AI with existing excavation workflows to maximize safety and precision?

Effective integration involves deploying AI-enabled sensors and software platforms that interface seamlessly with autonomous machinery and project management systems. Establishing standardized data protocols, continuous machine learning model updates, and cross-disciplinary collaboration among geotechnical experts, data scientists, and construction crews are crucial. This holistic approach ensures that AI insights translate into actionable decisions, reducing risks and enhancing overall project resilience. For more advanced strategies, industry professionals are encouraged to consult resources such as the Geotechnical Journal’s recent review on AI applications in subsurface engineering.

Engage with these innovative methods to future-proof your projects and stay ahead in the evolving field of underground infrastructure development.

Expert Insights & Advanced Considerations

Innovation Drives Efficiency in Subsurface Work

Applying cutting-edge geotechnical analysis and AI-enhanced soil characterization significantly reduces risk and increases accuracy in underground projects. Leveraging real-time data and adaptive machinery ensures that excavation adapts seamlessly to complex underground conditions, optimizing safety and resource utilization.

Precision Tools Transform Complex Environments

Utilizing high-resolution ground-penetrating radar (GPR) and sensor networks provides unparalleled insights into subsurface anomalies. These technologies enable engineers to preemptively address utility conflicts and unstable soil zones, minimizing delays and structural risks.

Integrating Virtual Reality for Pre-Construction Planning

Immersive VR simulations allow teams to virtually explore excavation sites, identify potential conflicts, and refine strategies before ground-breaking. This proactive approach reduces costly errors and environmental impacts, setting new standards for precision and safety.

AI Elevates Utility Detection Capabilities

AI algorithms synthesize diverse datasets—such as GPR scans, sensor feedback, and historical utility data—to generate highly accurate 3D underground models. This integration enhances utility detection, reduces utility strikes, and streamlines project workflows.

Future-Proofing with Smart, Adaptive Machinery

Autonomous excavation units equipped with AI-driven sensors and predictive analytics enable dynamic responses to underground surprises. This technological synergy maximizes operational efficiency, safety, and environmental stewardship in challenging subterranean environments.

Curated Expert Resources

- Hydrovac Drilling Technical Guides: Industry-leading manuals and case studies on vacuum excavation best practices and safety protocols.

- Geotechnical Engineering Journals: Peer-reviewed articles on soil analysis, utility detection, and subterranean risk management innovations.

- AI and Machine Learning in Geotechnics: Recent publications exploring AI applications for predictive soil stability and utility mapping.

- Virtual Reality in Construction Planning: Case studies demonstrating VR’s impact on reducing excavation errors and enhancing team collaboration.

Final Expert Perspective

As the landscape of underground engineering evolves, embracing advanced borehole and vacuum excavation strategies becomes essential for achieving unparalleled safety and precision. Integrating innovative technologies such as AI, VR, and high-resolution subsurface imaging empowers industry professionals to navigate complex environments confidently. To stay at the forefront of this dynamic field, continuously explore authoritative resources and engage with cutting-edge tools. Your expertise and proactive adaptation will shape the future of resilient, reliable infrastructure development. We invite you to share your insights or explore further resources to elevate your underground project capabilities.

This post touches on some of the most exciting advancements in underground excavation technology. I’ve recently been involved in a project where integrating ground-penetrating radar (GPR) with real-time sensor data dramatically improved our accuracy in detecting underground utilities. The ability to dynamically adapt our strategy based on live data not only increased efficiency but also significantly enhanced safety measures, especially in an urban setting with dense utility networks.

One aspect I find particularly promising is the use of AI-driven soil analysis, which can predict soil behaviors and potential hazards before we even start digging. It’s amazing how machine learning models trained on extensive datasets can identify patterns that human analysts might overlook. Given these innovations, I wonder: what are some of the biggest challenges teams face when implementing these advanced systems, especially in space-constrained or environmentally sensitive areas? Sharing real-world experiences could help others better prepare for adopting these technologies effectively.

The post offers a comprehensive look at how evolving technology—like high-resolution GPR, AI-driven analysis, and virtual reality—is transforming underground excavation. Having recently worked on a retrofit project in an urban environment, I can attest to how critical precision tools are for minimizing utility strikes and environmental disturbance. One thing I’ve observed is that despite these technological strides, the biggest challenge often lies in integrating new systems into existing workflows without disrupting ongoing operations. Effective training, cross-disciplinary collaboration, and establishing clear protocols are essential.

I’m curious, in your experience or industry reports, what strategies have proven most effective for overcoming resistance to adopting these advanced tools? Are there specific case studies that highlight successful integration, especially in highly constrained or sensitive sites? It seems that the key may not only be in technological capability but also in change management and stakeholder engagement, ensuring all teams are aligned on benefits and safety priorities.

This article provides a really insightful overview of the cutting-edge technologies shaping underground infrastructure in 2025. I’ve personally seen how the integration of AI-driven soil analysis and real-time GPR data can drastically reduce utility strikes and improve decision-making accuracy. What continues to challenge us, especially in densely built urban environments, is the initial setup of these advanced systems—often requiring substantial investment in training and calibration. I wonder how companies in the field are effectively managing this transition without disrupting ongoing projects? Have there been notable examples of efficient onboarding procedures or hybrid approaches that balance innovation with operational continuity? It’s exciting to think about how these tech advancements can be combined with adaptive, modular machinery for even greater safety and precision. Looking forward to hearing how others have navigated these implementation hurdles or if there are emerging best practices for seamless integration.