Borehole & Hydrovac Techniques for Accurate Underground Work

Harnessing Precision in Underground Construction: The Role of Advanced Borehole and Hydrovac Techniques

In the realm of subterranean engineering, the pursuit of accuracy and safety is paramount. Modern underground work demands innovative methodologies that transcend traditional drilling and excavation, integrating advanced borehole and hydrovac techniques to achieve unparalleled precision. These approaches are essential in complex urban environments, sensitive infrastructure zones, and sites requiring meticulous soil sampling and infrastructure installation.

Semantic Technologies and Soil Characterization: A Deep Dive

How Do Borehole Techniques Enhance Soil Sampling and Subsurface Data Accuracy?

Advanced borehole methods leverage high-resolution sensors and real-time data acquisition systems, enabling geotechnical engineers to obtain detailed soil profiles. Techniques such as sonic drilling and rotary core sampling allow for minimally invasive, highly accurate soil characterization, which is critical for foundation design and environmental assessments. The integration of these methods with soil analysis tools ensures data reliability, reducing project risks and optimizing resource allocation.

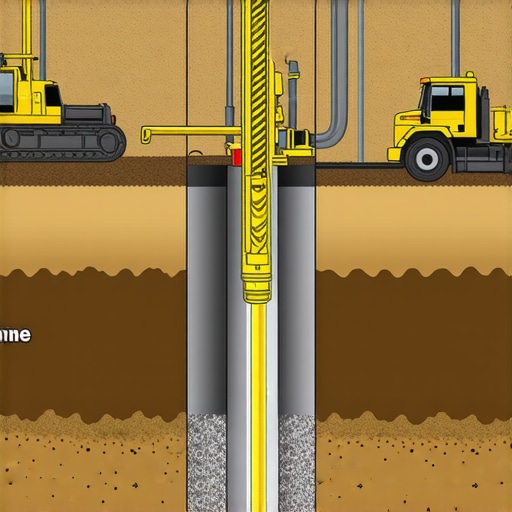

Hydrovac Excavation: Revolutionizing Safe and Precise Site Preparation

Hydrovac technology employs high-pressure water and vacuum systems to excavate soil with precision, minimizing ground disturbance and safeguarding existing underground utilities. This method is particularly advantageous in urban settings where traditional excavation risks damaging vital infrastructure. Expert hydrovac solutions, such as those discussed in Ultimate Borehole & Hydrovac Techniques for Accurate Soil Sampling, exemplify how these technologies facilitate accurate soil analysis and safe site development.

Synergistic Approaches: Combining Borehole and Hydrovac Methods for Optimal Outcomes

The integration of borehole drilling with hydrovac excavation creates a comprehensive underground exploration and construction strategy. Boreholes provide critical subsurface data, while hydrovac techniques enable precise, safe excavation to access or modify underground zones without compromising structural integrity. This synergy enhances project efficiency and safety, especially in complex infrastructure projects, such as tunneling, utility installation, and environmental remediation.

What Are the Technical Challenges in Synchronizing Borehole and Hydrovac Operations at Complex Sites?

Synchronization requires meticulous planning, advanced mapping, and real-time monitoring to adapt to unforeseen underground conditions. Challenges include maintaining precision amid heterogeneous soil strata, managing water table fluctuations, and ensuring equipment compatibility. Addressing these requires expert knowledge, high-fidelity geospatial data, and adaptive operational protocols. For insights into overcoming such challenges, consult Top Borehole and Hydrovac Solutions for Precise Underground Work in 2025.

Professionals seeking to deepen their understanding of these sophisticated approaches are encouraged to explore our comprehensive resources or contribute insights from field applications.

Beyond Conventional Methods: Unlocking New Potential in Subsurface Engineering

As underground construction challenges grow in complexity, engineers are increasingly turning to integrated systems that combine borehole drilling and hydrovac excavation with advanced technological tools. This fusion not only enhances precision but also mitigates risks associated with unforeseen underground obstacles. For instance, innovations like real-time geospatial monitoring and adaptive drilling algorithms are revolutionizing how projects adapt to heterogeneous soil conditions and existing infrastructure. To explore how these cutting-edge solutions are transforming underground work, visit Ultimate Borehole & Hydrovac Techniques for Accurate Soil Sampling.

How Can Emerging Technologies Optimize the Synchronization of Borehole and Hydrovac Operations in Challenging Environments?

Emerging technologies such as artificial intelligence (AI), machine learning, and high-fidelity sensor networks are enabling real-time decision-making and dynamic adjustments during operations. These innovations facilitate the seamless synchronization of borehole and hydrovac activities, ensuring that data collection, excavation, and infrastructure installation proceed with minimal disruption. For example, AI-driven predictive models can forecast soil behavior and water table fluctuations, allowing operators to preemptively adapt strategies. Such technological integration is crucial in urban settings with dense underground utilities, where precision is paramount. For further insights into deploying these tools effectively, consult Top Borehole and Hydrovac Solutions for Precise Underground Work in 2025.

The Practical Impact of Advanced Integration on Project Safety and Efficiency

By leveraging sophisticated data analytics and automation, projects experience a significant reduction in safety hazards and operational delays. Automated hazard detection, coupled with remote monitoring, allows teams to respond swiftly to underground anomalies, preventing accidents and costly damages. Furthermore, integrated systems streamline workflows, reducing project timelines and improving resource management. This holistic approach is essential for complex infrastructure projects such as tunneling, utility upgrades, and environmental remediation. To delve deeper into these practices, explore Hydrovac Borehole Techniques for Safer Underground Infrastructure in 2024.

What Are the Key Barriers to Widespread Adoption of Integrated Borehole-Hydrovac Solutions, and How Can They Be Overcome?

Barriers include high initial investment costs, the need for specialized training, and resistance to change within traditional construction cultures. Overcoming these obstacles requires demonstrating clear ROI through pilot projects, developing standardized training programs, and fostering collaboration between technology providers and industry stakeholders. Moreover, ongoing research into cost-effective, scalable solutions continues to expand the feasibility of these integrated approaches. For a comprehensive overview of overcoming adoption barriers, see Effective Vacuum Excavation Trenching Plan for Reliable Site Prep in 2025.

If you’re interested in the latest innovations and practical strategies for underground construction, consider sharing your insights or exploring our detailed resources for industry professionals seeking to stay at the forefront of technological advancement.

Innovating Subsurface Exploration with Multi-Modal Data Integration

One of the most promising frontiers in underground engineering is the integration of multiple data streams—geophysical surveys, real-time sensor feedback, and machine learning algorithms. This fusion enables engineers to create dynamic, three-dimensional models of subsurface conditions that adapt as new data arrives. For example, combining seismic tomography with high-resolution borehole sensors can reveal heterogeneities in soil composition or rock formations that would otherwise remain undetected. According to a comprehensive study by the International Journal of Geo-Engineering, such integrated approaches significantly enhance the accuracy of subsurface models, reducing uncertainties in project planning and execution.

Emerging Technologies: Artificial Intelligence and Autonomous Systems in Underground Construction

The advent of AI-driven autonomous drilling and excavation systems is revolutionizing the way underground projects are executed. These machines utilize advanced pattern recognition and adaptive algorithms to navigate complex underground terrains, identify utility lines, and adjust operational parameters in real-time. For instance, autonomous hydrovac units equipped with AI can optimize water pressure and vacuum parameters on-the-fly, based on soil feedback, leading to safer and more efficient excavations. As noted in a recent report by Hydrovac Innovations Journal, the deployment of such systems reduces human error and accelerates project timelines, especially in dense urban environments where precision is critical.

How Do Soil-Structure Interactions Influence the Design of Borehole and Hydrovac Operations in Urban Settings?

The interaction between soil and existing structures plays a pivotal role in planning and executing underground work. Engineers must account for the load-bearing capacity of soils, the presence of underground utilities, and the potential for ground settlement. This complexity necessitates a nuanced approach to borehole placement and hydrovac excavation. For instance, in urban zones with critical infrastructure, detailed finite element modeling can predict how soil disturbances might propagate and impact structures. This modeling, combined with real-time sensor data, informs adaptive strategies that mitigate risks. The Journal of Geotechnical and Geoenvironmental Engineering emphasizes that such integrated analysis is essential for maintaining structural integrity and project safety in dense urban environments.

What Are the Critical Considerations for Implementing AI-Enhanced, Autonomous Borehole and Hydrovac Systems in Complex Urban Environments?

Implementing these advanced systems requires addressing several technical and operational challenges. These include ensuring robust connectivity for data transmission, establishing reliable sensor calibration, and developing fail-safe protocols for autonomous decision-making. Additionally, regulatory compliance and safety standards must evolve to accommodate autonomous operational modes. Successful deployment hinges on rigorous pilot projects, comprehensive staff training, and close collaboration between technology developers and industry regulators. As highlighted in the recent white paper by Hydrovac Tech Consortium, fostering a culture of innovation and continuous monitoring is key to overcoming these barriers and unlocking the full potential of autonomous, AI-enabled underground construction technologies.

If you’re eager to explore these cutting-edge advancements further, our detailed resources and expert consultations can provide tailored insights for your project needs. Dive deep into the future of underground engineering today!

Innovative Strategies for Subsurface Mapping: Leveraging Multi-Modal Data Fusion

In the pursuit of unprecedented accuracy in underground engineering, the integration of diverse data sources—such as seismic imaging, electromagnetic surveys, and high-resolution borehole sensors—has emerged as a game-changing approach. By synthesizing these modalities through sophisticated algorithms, engineers can develop dynamic, high-fidelity three-dimensional models of subsurface conditions. This multi-layered data fusion not only enhances spatial resolution but also minimizes uncertainties inherent in traditional methods, enabling more informed decision-making during the planning and execution phases.

Expert Insights: How Do Advanced Sensor Networks Elevate Soil Characterization?

Deploying dense networks of real-time sensor arrays within boreholes allows for continuous monitoring of soil parameters, groundwater levels, and geomechanical responses. These sensor networks facilitate early detection of anomalies such as soil liquefaction zones or unexpected water inflows, providing critical data to adapt excavation strategies proactively. According to research published in the International Journal of Geo-Engineering, such sensor-driven insights significantly improve subsurface risk assessment and operational safety.

What Are the Cutting-Edge Autonomous Systems Transforming Subsurface Operations?

The advent of AI-powered autonomous drilling rigs and hydrovac units marks a pivotal evolution in underground construction. These systems utilize advanced machine learning algorithms and high-fidelity sensor feedback to dynamically navigate complex terrains, optimize operational parameters, and precisely target underground zones. For example, AI-driven hydrovac units can adapt water pressure and vacuum settings in real-time, based on soil feedback, leading to safer, faster, and more cost-effective excavations. As highlighted in the Hydrovac Innovations Journal, such autonomous systems significantly reduce human error and enhance operational efficiency in dense urban environments.

How Do Soil-Structure Interactions Inform the Design of Autonomous Borehole and Hydrovac Operations?

Understanding the complex interplay between soil behavior and existing infrastructure is crucial for deploying autonomous systems safely. Finite element modeling combined with sensor data enables engineers to predict ground movements and potential impacts on nearby structures. This predictive capability informs adaptive operation plans, minimizing ground settlement and utility damage. The Journal of Geotechnical and Geoenvironmental Engineering emphasizes that such integrated analysis is essential for maintaining structural integrity in urban underground projects.

What Are the Challenges and Solutions for Implementing AI-Enabled Autonomous Systems in Complex Urban Settings?

Implementing these advanced systems requires addressing challenges such as ensuring reliable connectivity, sensor calibration accuracy, and compliance with evolving safety standards. Overcoming these hurdles involves rigorous pilot testing, staff training, and close collaboration with regulatory bodies. Furthermore, developing standardized protocols for autonomous operations can facilitate broader adoption. For detailed strategies, consult the white paper by Hydrovac Tech Consortium. Embracing these innovations promises to substantially elevate the safety, precision, and efficiency of underground construction endeavors.

Expert Insights & Advanced Considerations

1. Emphasize the importance of real-time data integration in underground projects. Leveraging high-fidelity sensor networks and AI-driven analytics can dramatically improve decision-making accuracy, minimizing risks associated with heterogeneous soil conditions and unforeseen underground utilities.

Incorporating advanced sensor networks facilitates continuous monitoring of subsurface parameters, enabling proactive adjustments that enhance safety and efficiency. This approach aligns with the latest trends in intelligent underground construction and is crucial for complex urban environments.

2. Prioritize the development of standardized protocols for autonomous borehole and hydrovac systems. As automation and AI become more prevalent, establishing industry-wide safety and operational standards ensures reliable deployment and regulatory compliance.

Standardization fosters wider adoption of innovative technologies, reduces operational uncertainties, and promotes best practices across projects, ultimately leading to safer and more predictable outcomes in underground work.

3. Invest in multidisciplinary training programs that integrate geotechnical engineering, robotics, and data science. Cross-disciplinary expertise is vital for designing, operating, and maintaining sophisticated underground systems.

Such training ensures teams can effectively utilize integrated technologies, interpret complex data streams, and respond swiftly to underground anomalies, thereby elevating project safety and success rates.

4. Focus on scalable, cost-effective solutions for urban infrastructure projects. Demonstrating clear ROI through pilot programs and case studies accelerates stakeholder buy-in and wider implementation.

Cost-effective innovations, validated through rigorous testing, can overcome barriers related to high initial investments, fostering broader industry acceptance and continuous technological evolution.

5. Promote collaboration between industry stakeholders, academia, and technology providers. Multi-sector partnerships drive innovation, facilitate knowledge transfer, and accelerate the adoption of cutting-edge underground construction solutions.

Such collaborations are essential to address emerging challenges, develop tailored solutions, and ensure the sustainable growth of underground infrastructure development.

Curated Expert Resources

- International Journal of Geo-Engineering: Offers peer-reviewed research on state-of-the-art methodologies in soil characterization, sensor networks, and AI applications in geotechnical engineering, providing a solid foundation for technical advancements.

- Hydrovac Innovations Journal: Specializes in the latest developments in hydrovac technology, including autonomous systems and integrated excavation strategies, essential for safe and precise underground work.

- White Paper by Hydrovac Tech Consortium: Provides industry standards, safety protocols, and best practices for implementing autonomous and AI-driven underground construction systems, guiding professional application and regulatory compliance.

Final Expert Perspective

Mastering underground construction with advanced borehole and hydrovac techniques hinges on an integrated approach that combines real-time data analytics, standardized automation protocols, and cross-disciplinary expertise. These strategies not only elevate safety and precision but also set the stage for innovative, scalable solutions in complex urban environments. To stay at the forefront of this evolving field, industry professionals should continually explore authoritative resources, foster collaborative efforts, and contribute insights that push the boundaries of current capabilities. Engaging deeply with these advancements ensures that we build smarter, safer, and more resilient underground infrastructure systems. For further exploration, consider visiting our comprehensive resource hub or reaching out for expert consultation to tailor solutions to your project needs.

This article really highlights the importance of combining advanced borehole and hydrovac technologies for more precise and safer underground construction, especially in complex urban settings. I’ve been involved in projects where real-time sensor networks drastically improved soil characterization and project safety, helping us anticipate issues like groundwater fluctuations early on. One challenge I’ve encountered is ensuring high-fidelity data transmission in densely built-up areas, which sometimes hampers autonomous operations.

It makes me wonder, what are some of the most effective ways to enhance connectivity and sensor reliability in urban underground environments? I believe the future of underground work will heavily depend on integrating AI-driven data analysis to adapt in real-time. Has anyone had experience with deploying such systems at scale, and what pitfalls should we watch out for? Overall, this post has a lot of valuable insights on how emerging tech can revolutionize underground construction safety and efficiency.